Details of a 250 Engine

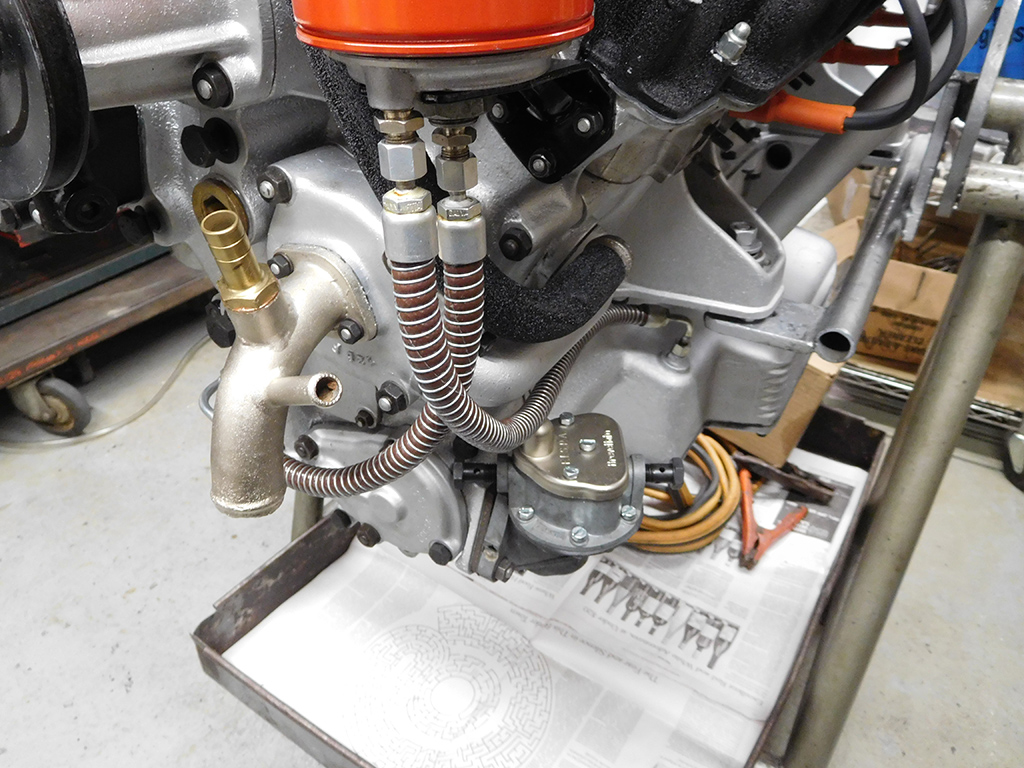

As they say, the devil is in the details! The 250 engine is coming together nicely, but there are still a bunch of things that need attention. I fabricated the oil lines for the bypass oil filter, and installed the mechanical fuel pump. Before installing the fuel pump, I bench tested it to make sure it was pumping properly. I also checked the amount of movement the push rod moved on the engine side to make sure it matched the fuel pump.

We installed the generator with the freshly plated bracket to make sure it would fit with the correct spacers and bolts. I removed the pulley for cleaning and painting, as it looks pretty cruddy next to all the fresh parts!

The rear coolant pipe was also plated and ready for installation. I’ll fabricate a new clip for this pipe which is often lost or missing and certainly not with this pipe when we took it off the engine.

The screws for the distributors were also ready for installation. White cadmium plating with black oxide lock washers are what is correct.

The list of details for a Vintage Ferrari is pretty long, but it kind of comes second nature when you do it long enough. Some people may scoff at the amount of time we spend making everything right, but I feel the rewards of having everything look original is worth it!

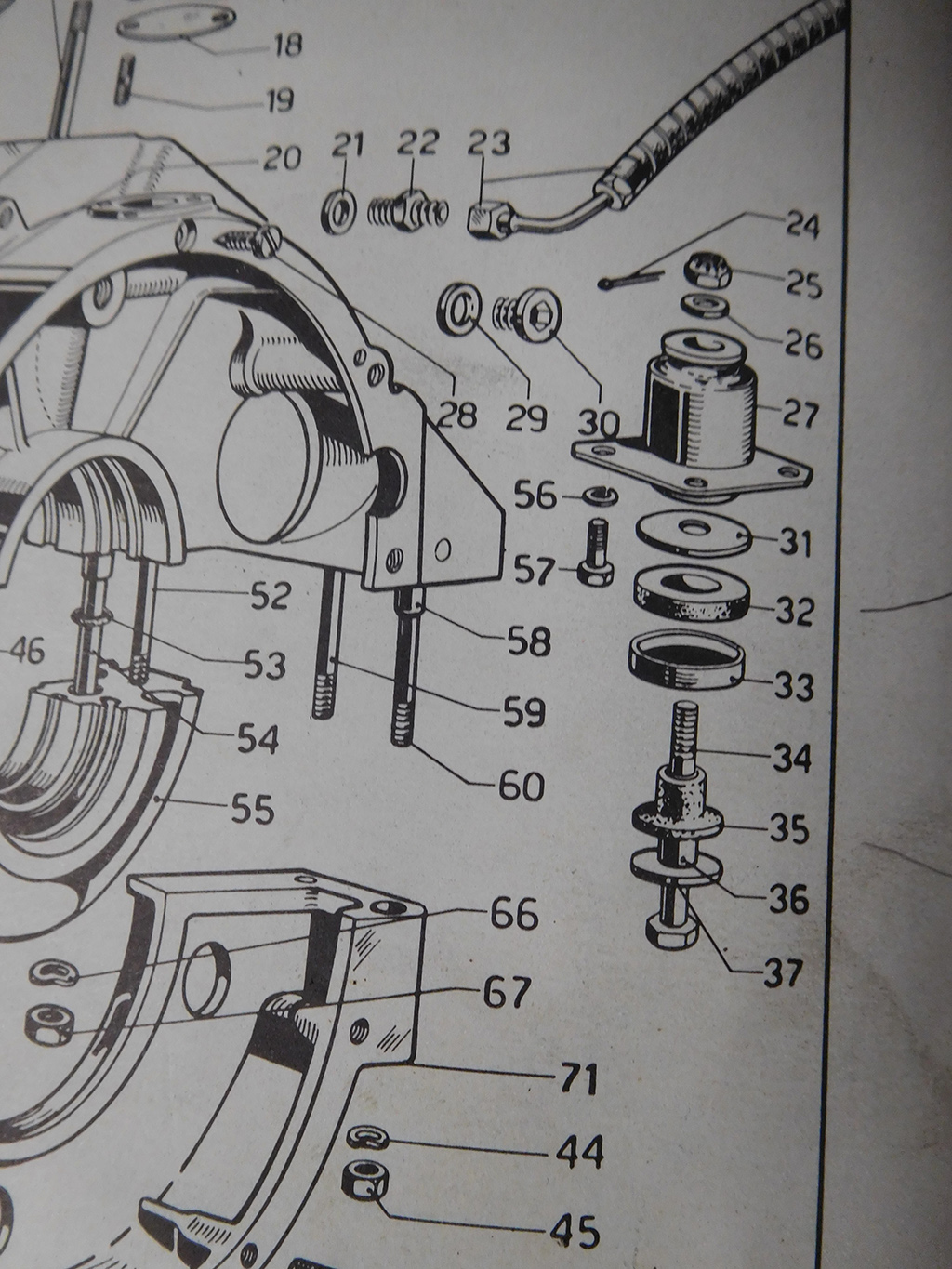

A common missing part on 250 4 mount Ferrari engines is a pair of bushings that go on the rear mount of the engine. Part #35 and #32 were made of soft bushing material that easily disintegrated so many people didn’t even know they were supposed to be there. The height difference can often throw off the alignment of the engine to the rear axle. The total height of this bushing was about 10 mm, but the angle this gives to the engine can be significant when measuring the angle of the transmission.

Francois likes to make these bushings out of Teflon, so I machined up a set following his notes. I’ve been told by material experts that teflon will compress over time, and perhaps polyurethane is a better material, but Francois has never had issues with this set up.

Here’s the bushing installed and ready to mount the engine in the car.