What’s Knocking Back There? Ferrari 250GTE Rear Suspension

After tuning up a Ferrari 250GTE, I took her out for a test drive, and although my tuning sounded good, I was bothered by a persistent knocking coming from the rear of the car.

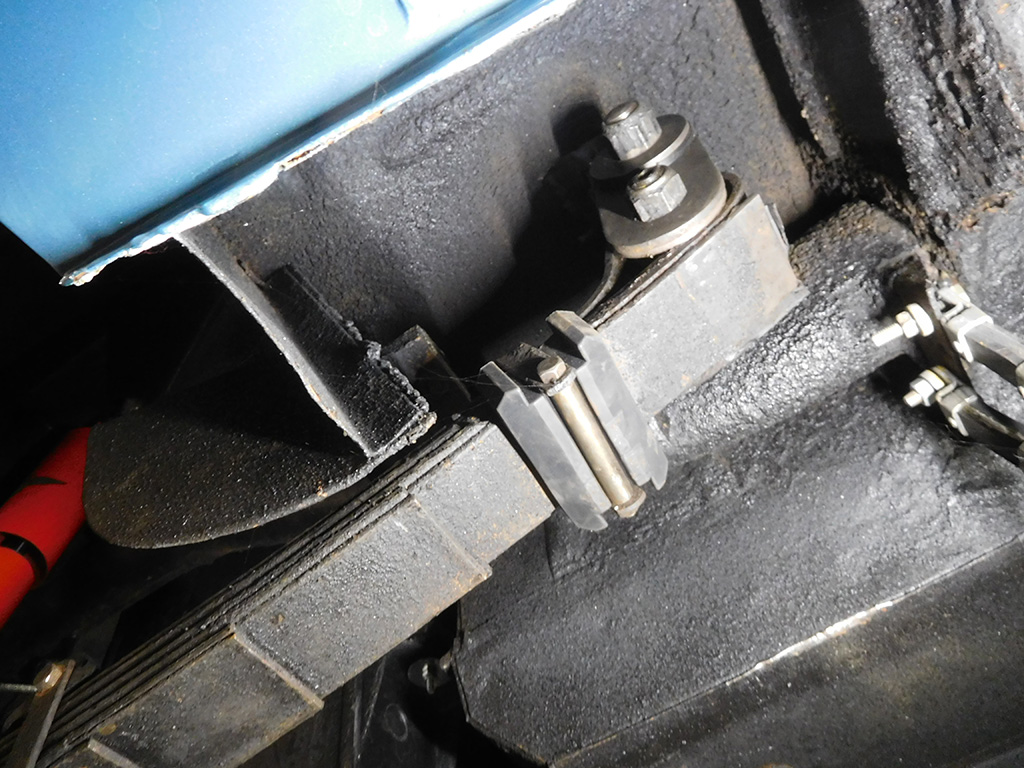

One peek underneath, and I could clearly see the source of the noise. The rear leaf spring shackle was installed upside down and banging against the truck floor!

To show the difference, here’s a picture of another GTE with the rear shackles installed properly. Notice how the leaf spring sits below the shackle allowing the shackle to point downwards.

Vintage Ferrari suspensions are tricky, and I’ve seen this mistake often, causing all sorts of problems from knocking, to incorrect ride heights. The leaf springs are a little different than other leaf spring cars I’ve worked on where when they are removed from the car, the Ferrari leaf spring will try to return to the shape of a “U.” When removing or installing these springs, they have to pulled flat with a tool so they can me serviced.

I started with one side at a time, and removed the shock and the spring to make the rear suspension work as it was intended.

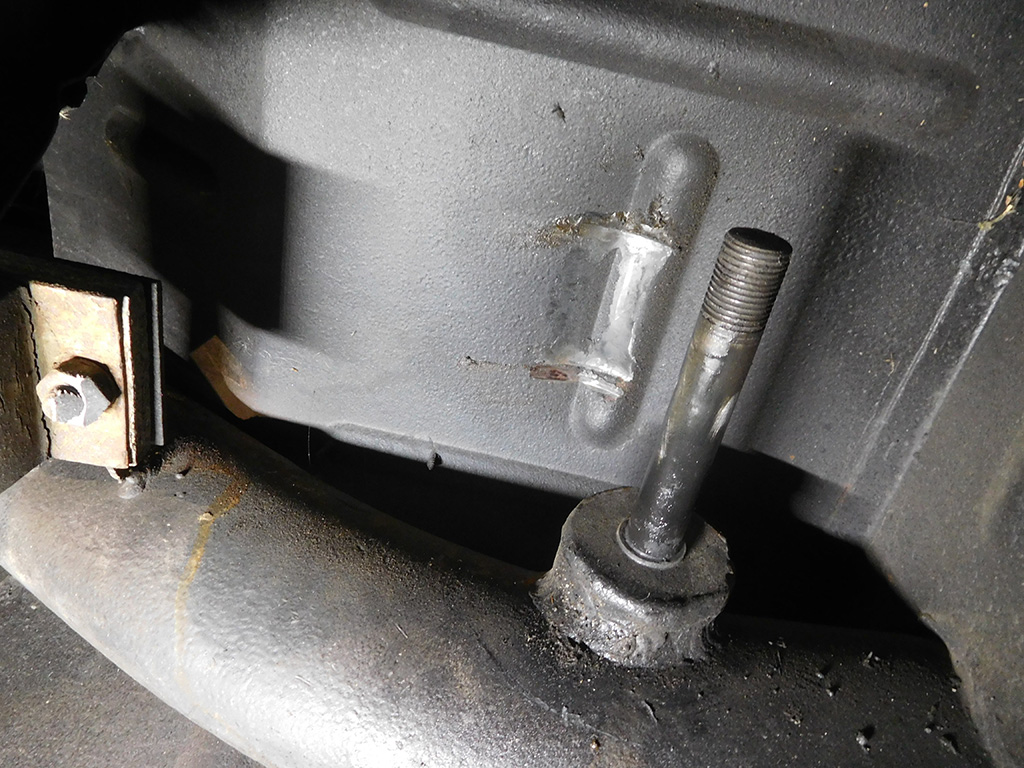

With the spring removed, the source of the knocking was pretty obvious.

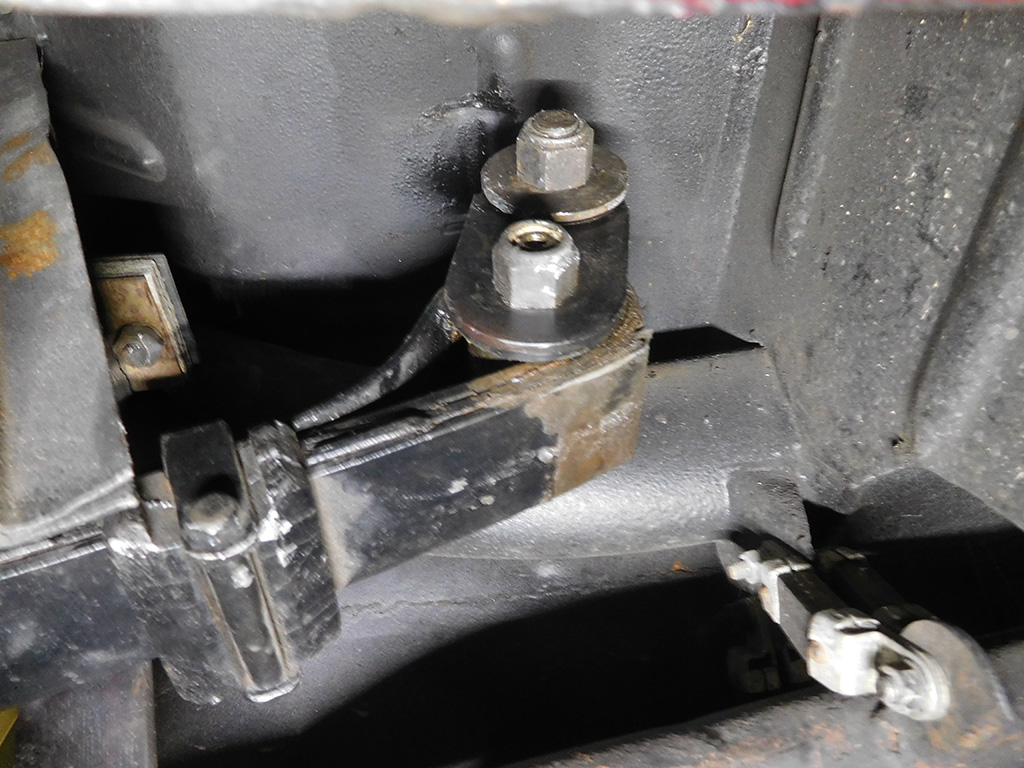

Someone had obviously been inside this suspension before because I found replacement parts installed. Unfortunately, I felt these were the wrong parts and the plans were to replace these with fabricated bushings made of acetal plastic (Delrin), the white rod pictured at the bottom of this picture.

What a previous shop had used to replace the spring eye bushing was a rubber “silent block” type bushing. This might not have been the shop’s fault, as I know plenty of Ferrari Parts Suppliers that sell this bushing as a replacement part for the spring eye bushing, but here’s where I disagree.

The bolt that secures the spring eye to the shackle is hollow because it also accepts grease to lubricate what it holds in place.

Here’s a picture of an original bushing I replaced on another car. They were made of a soft, greaseable, bushing. Unfortunately, the material Ferrari chose wore out prematurely, and needed to be replaced with something more durable, just not a rubber bushing because that won’t accept any grease!

I custom make Delrin bushings, drill out holes in the center sleeve and cut channels in the bushing to accept grease. These should out last the life of the car, and work as this leaf spring bushing was designed!

Another issue I found on this car was it was also missing these side plate pieces. I made them out of acetal plastic as well, but managed to find it in black.

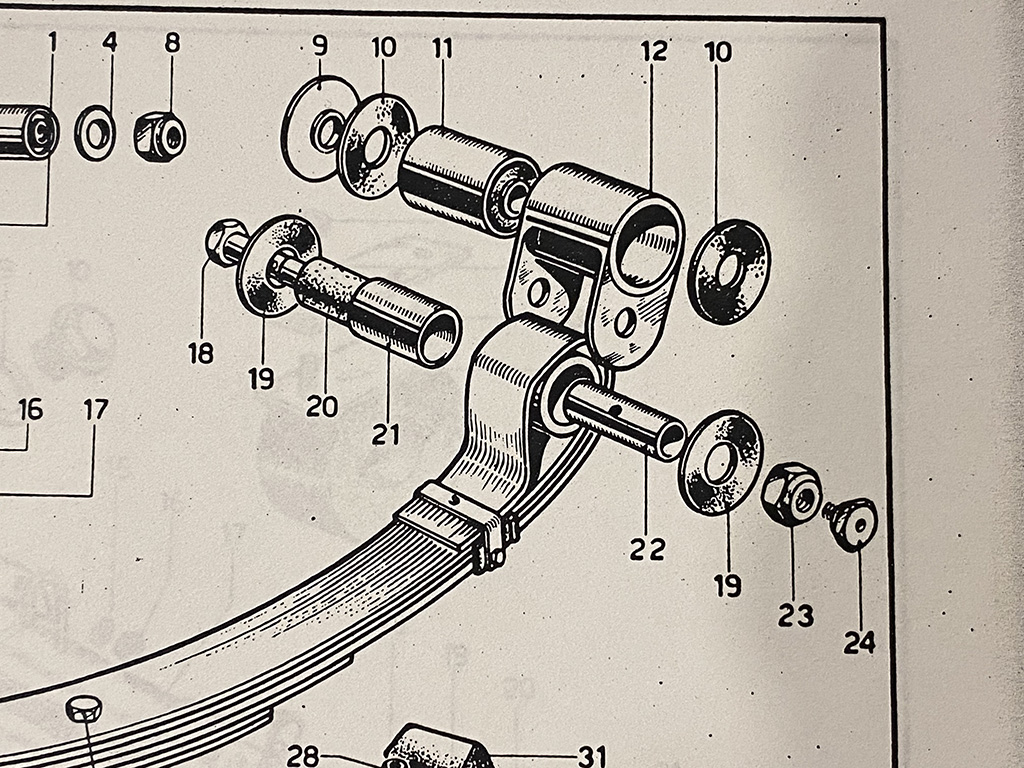

To prove I’m not just making this stuff up, look at the parts book drawings. This one is from a 330GT parts book which basically has the same suspension set up as the GTE. Part # 20 is drawn as a separate part while #11 is shown as a unit (silent block bushing). It even shows the hole in the sleeve for spring eye bushing.

I was taught by many of the mechanics that work on these old Ferraris that when in doubt, refer to the parts book. They’re actually drawn with quite a bit of accuracy.

I can’t thank my friends Craig and Steve for making this spring compressor for me several years ago. I used to use a bar Francois had made at his shop, and I would be scared for my well being every time I had to use it! Although a SIII GTE has less tension on the rear leaf spring than the earlier cars, the stored energy of any spring can potentially hurt you if it’s not properly secured. I’ve modified this one to work for me, but I feel much safer working with this one!

One thing I had to check when I reinstalled the springs to its proper orientation was whether the limiting straps were properly adjusted. Allowing the rear springs to droop too far when the car is raised can allow the spring shackles to violently pop back in the incorrect over center position with the springs going back into the shape of a “U.” The length of these limiting straps is crucial to preventing this from happening.

With everything properly installed, I moved onto the other side to correct the other spring. Once I had everything corrected, I’ll lower the car to ride height and tighten all the bolts. It’s a big job, but this should make the car drive and handle as it should, and be a lot quieter!

Here’s a video of the process!