Getting 5053 back on the Road

1/7/11

Getting 5053 back on the Road

I’ve been taking my spare time to work on my car trying to get the brakes back together. I’m anxious to try out the new brake equalizer that Karp’s Brake Service rebuilt, but there have been some minor hang ups. A brake line by one one of the front calipers was having trouble sealing, so I decided to make a new flare end. Since the fitting was getting chewed up, I ordered new fittings to do the job right.

Fedhill has the a selection of fittings for the English made brake calipers, and I ordered some extras so I would have them for the future.

I also ordered new brake bleeder screws for my car. They’re slightly different that the original ones that came on the car. The original bleeder screw had an indent on the end for a ball bearing that drops down inside the caliper. I believe this ball was supposed to act like a check valve, but through the years, the ball rusts, deforms, an can even crack the end of the bleeder.

The new bleeder is designed to seal directly to the bottom of the bleed hole and eliminates the ball. Since my bleeders were cracked and having trouble sealing, now was the time to upgrade.

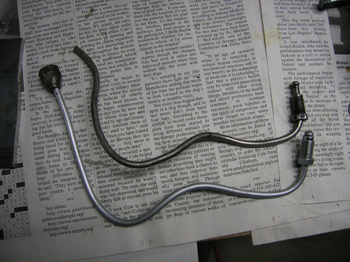

There are two types of flares on this line, one being a European bubble flare, and the other a SAE double flare. The appropriate flare was made and a copy was ready to install. If I were trying to make a show car, this line would have been copper plated, but my car is more for driving than showing!

While I was under the car, I noticed a little bit of coolant weeping out from a coolant hose. On closer inspection, I saw that a coolant pipe was not sealing well. I pulled the pipe to find the inside of the pipe badly rusted. After sandblasting, a pinhole popped through. I decided now was a good time to try an experiment. Besides the small pinhole, the pipe was still in decent shape, so I took it down to a local powder coater to see what could be done. I wanted to know if he had a powder coat finish that could seal this piece up inside and out and withstand the constant submersion in coolant. I’ve seen ceramic coatings applied to these pipes, but I wanted to try out powder coating as an alternative. Since the next step would have been to fabricate a new pipe, now was a good time to try this out.

Reminder: If you have a Ferrari related project, car, or idea you’d like to explore, I’d love to talk to you. I can also help if you’re thinking of buying or selling. This website represents what I love to do, share, and how I make a living, so if you’d like to do something together, let me know. It all begins with an e-mail!

Previous Restoration Day

Next Restoration Day

Home page