Dodging the Differential Bullet!

2/22/02

Dodging the Differential Bullet

If a picture can tell a story, and you’ve been following this one, you can tell I got the #$@%# axle tube out! What a struggle!

The bane of my day centered around this one stubborn bolt that goes through this bushing. François tried during the week to bash it out, so I called him from my “day job” to see if he had any luck. He basically said one thing. “Eees really stuck!” I knew coming to work today, the only choice I had was to cut the bolt on each side as close to the bushing as possible to free it from the axle tube. I used a combination of cut off wheel, hacksaw blade, and sheer determination to cut the hardened steel bolt, and eventually I won the battle.

My problem now is what to do about this seized bolt? The bushing is in good shape, and I would hate to destroy it. I told François I’d like to try drilling it out, but he says it’ll take me forever to drill that bolt out. The bushing seems to have a inner and outer sleeve, but pressing out the the bushing seems just as hard, considering how seized the inner sleeve is. The other problem is getting this locating arm out of the car to press this sleeve out. The other end of this arm is just as stuck as this one! The worst case is we have to destroy the bushing by burning it out with a torch. I’ve also heard of a trick Porsche guys use where they chill the rubber bushing with liquid nitrogen and shatter the frozen rubber. Hmmm, I wonder how hard it would be to get my hands on some liquid nitrogen…anyway, I’m open to any suggestions! E-mail me.

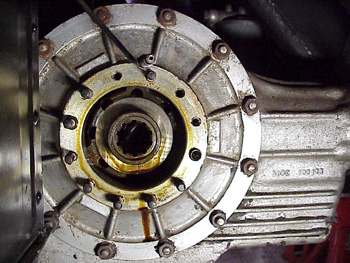

Well, so far so good. François took out the axle shaft during the week, and it looked pretty good without any signs of bad rust. Inside the axle I found some “chocolate pudding” but the oil part of this concoction seemed to have done it’s part in keeping rust from forming. Maybe using that 250 Weight oil kept the water from displacing a lighter weight oil, but whatever the case, after cleaning out this crap, the inner bearing moved freely, and no pitting was found.

From what I could see at this point, it looked promising. Oil was still coating many of the parts I could see, and there was no “brown mayonnaise.” The next step was to remove all the nuts to remove the inspection cover.

I was very pleased with what I saw after the cover came off. There were some small rust spots on the gears, but they were all superficial. You could make out a water line inside the gear case, but I think the heavy gear oil did a great job sticking to the metal parts. François came over after all my struggling and confirmed my discoveries. He felt good after removing the axle shaft and finding very little signs of rust in the bearings earlier in the week, so seeing the ring and pinion look this good gave him good reason to have me put everything back together!

Unfortunately it’s going to take some work to get everything back together! Besides the bushing dilemma, I need to replace two hardened bolts I cut from the spring plates. They are 10 mm X 1.0 pitch at about 81 mm. After I buy them, I’ll need to take them to the CBS machine shop to get cotter pin holes drilled. François has already begun the process of repairing the damage we did the to axle tube by bashing away at the stuck bolts. Some of the hangers were bent and cracked using really big hammers! All the pieces I took off also need to get a good cleaning, and painting, because I don’t plan on taking any of this stuff off again any time soon (famous last words!).

I’m now going to go and rest my weary body so I can hit it again next week!

Previous Restoration Day

Next Restoration Day

Ferrari Home Page