Carbs, and My First Drive!

10/9/02

Carbs and My First Drive!

I managed to find a day this week where we weren’t too busy that I could take a day off and work on the car. If all went well, I would have my very first drive in the 330 America, and after over three years of work, I couldn’t let my day job get in the way!

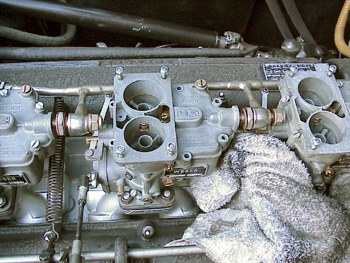

My first task was to get the new needles and seats for the float mechanisms installed. This would eliminate my problems with the stuck floats. I unbolted the fuel lines to the carbs once again so I could pull the carburetors.

This picture shows the top of the carburetor with the float hanging down.. The needle and seat (arrow) limit the amount of fuel into the carburetor. As the fuel bowl fills with fuel, the float rises, presses against the needle, and eventually cuts off fuel to to the carburetor. It works very much like a toilet.

If you remember, here’s a picture of the new needles and seats.

The old seats are a slightly different design. The needle material is different than the seat. Some people think the dissimilar material is one cause for the floats hanging up.

The new needles seem to be made of the same brass of the seat, and have a small spring loaded steel ball to contact the float. I would assume this modification is an improvement over the older design.

The spring loaded needle made for setting the float level a little trickier. The high level of the float for my carbs is 3 mm. François has a rod that is precisely this thickness to make measuring the float level easier. I had to make sure the floats were set just as the tab touched the needle, not after it compressed the spring. Any adjustments are made by physically bending the tabs that touch the needle. The low level position of the floats for my carbs is 10 mm, and is done much in the same way using a caliper to measure the distance. After removing each float mechanism, installing new needles and seats in three carbs, reinstalling each float, reassembling the fuel lines, and checking for fuel leaks, I was finally ready to try and drive my car!

It took nearly 20 minutes more after I got the carbs on before I could actually drive the car. Things like the front license plate, and rear view mirror needed to be attached before I set off. After all that, I still needed to jump start the car to get the weak battery enough power to fire the V-12, but eventually I got her lit!

If pictures are worth a thousand words, these tell you of the first 50 miles I drove in a car that has taken me three years to get to this point! Here’s the play by play:

After I got the car warmed up, I checked for fuel leaks, and anything burning near the exhaust. I carefully pulled out of François’ shop, and drove to the main road. Before I took off, I popped open the hood once again to see how the fuel bowls were doing. One of them was dripping slightly into the carburetor, but I decided I’d come too far to turn back. I slipped the transmission into first gear and headed out!

The clutch take up was smooth, and there was no whine in 1st. The carbs were popping, and spitting the whole time, but that was probably that one carb misbehaving. Second gear slipped into place like a rifle bolt, and she pulled strongly. I was shifting at 3000-3500 until I felt more confident. I couldn’t believe that as I got into third gear, I saw a police car turning off the main road! As I passed, I saw that he didn’t even notice me, so I pushed on. I decided to turn around after a few more minutes to go back to the shop to have another look under the hood, and around the car. As the engine, exhaust, and mechanical components got warm, all sorts of odors began to fill the cabin. Some I recognized as paint being burned off the mufflers, or oil burning off the headers, but there were a few that I did not readily know. Going back to the shop would give me a chance to look around, and assure I wasn’t being followed by a trail of flames!

Everything was checking out, and when I returned, I asked François to help take her out for a spin to get his impressions. As we headed out and took her through the gears, François listened to the car. By the time 4th gear arrived, we noticed no vibrations, or shaking in the drive line. As he reached for the overdrive, he noticed it wasn’t engaging. I added that to the growing list of things to do. The engine was still spitting, but it seemed not as bad. The master mechanic explained that the engine was still cold, and it takes quite a while for a Ferrari engine to get fully warm. He suggested to just drive the car as much as possible to break her in, and if the little problems persist, he can adjust them later. His belief, is it will all get better as I drive the car. By the time we returned to the shop, I looked down the throat of the carburetor that was previously leaking, and it was now bone dry. It looked like things were already beginning to break in!

After a few more adjustments, I got ready for some more driving! I wanted to take her out on the highway to see how she handled. I double checked my knock offs to make sure they were tight, and headed out. Taking the back roads to avoid New York State (I haven’t gotten the car inspected yet), I drove it to the interstate. At 85 miles an hour in 4th gear, she was tracking smooth and straight, but this speed was brief. At 70 and keeping with traffic it was smooth, loud, but smooth.

When I got back and told François about the smoothness, he congratulated me on my luck. He explained that many old Ferraris can have strange vibrations that are not easy to find. Not having any drive line vibrations saves me the aggravation of trying to hunt them down. Today’s drive also shows that the effort in making that hub adapter for balancing the Borranis was also successful because I felt no vibrations from the wheels!

I shot video of my first drive, so look forward to it posted on this site. I’m still reviewing in my mind the events of today, so perhaps you’ll hear more as I get my thoughts organized. All I can say is…I DROVE MY FERRARI!!!

Previous Restoration Day

Next Restoration Day

Ferrari Home Page