Carb Parts, and Grille Assembly

6/27/03

Carb Parts, and Grille Assembly

I stopped by Westport Precision to pick up some carburetor parts that Mike Sewell made for François. The one on the right is the one that came off a six carb set-up. It’s a throttle linkage, and is specific to the Ferrari V-12s with 6 carbs. When a customer wants six carbs, they will also need six of these to make the whole deal work. Mike had all the sheet metal cut and bent, and the rods machined and welded, so I picked them up today. Now all François has to do is have the part nickel plated, and the carbs will be done. Mike will be glad to hear that when François saw these brackets, he looked them over, and simply said, “That guy, he does good work!”

Staying busy with the work Mike has done for me, I decided to work on the grille today. The horizontal pieces still needed to be fitted to the grille by bending the tabs to the correct angles to match the curve of the grille shell. Although the bars show where they should be bent, they don’t exactly line up. At first, I tried to use cardboard templates to measure where the bends should be, but finally ended up eye-balling the bends with some of the extra pieces, to make perfect bends for the final pieces.

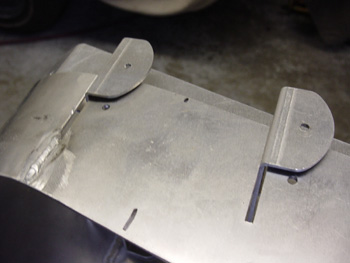

I used François’ sheet metal brake to make the bends, and it took several trips between the grille and the brake to fit everything together. Getting all the bars to fit tightly together took just the right amount of persuasion. I even used a rubber mallet to hammer everything home that last little bit.

The last vertical piece on each end of the grille shell still needed to be fitted. A weld exists here, so the alignment needed some slight adjusting. I got out my Dremel tool with a fiber disk cutoff attachment, and widened the slot on both ends.

Now the whole grill slides together perfectly.

Another step of the grille fabrication is to clean up these welds for polishing. With the whole grille assembled and installed, they won’t be too noticeable, but I would like to get them to disappear as much as possible.

I had a tiny drum sander attachment for the Dremel, so I tried it out with decent results, but the sandpaper wore out too quickly. I think I’ll have to buy a carbide burr used for removing metal for the Dremel so I can take most of the weld off before the finish sanding.

The next order of business on this grille is to fit it to the chrome surround that bolts to the nose of the car. There are two locating tabs that the act like a key way for the aluminum shell. I’ll save this procedure for the next time!

Previous Restoration Day

Next Restoration Day

Home page