Mechanical Fuel Pump I

9/15/10

Mechanical Fuel Pump I

Since my car is dead in the water without the brake equalizer parts, I decided to try and figure out the issue with the mechanical fuel pump. After speaking with several shops and what they do about rebuilding their mechanical fuel pumps, there does not seem to be consensus. (I’m not surprised) They mostly agree, however, that the rebuild kit available is not perfect, and there usually requires some kind of modification to the parts.

Years ago, I bought a fuel pump rebuild kit from Partsource that had the original Fispa check valves, but from what I understand, these are no longer available.

The original one-way valves pictured on the bottom have been replaced with the aluminum ones in the top of the picture. The brass valves come in two sizes with the larger valve for the intake side of the pump, and the smaller valve for the output side of the pump.

The original material used for the check valve seems to be a disc of a phenolic material, while the replacements use a piece of rubber.

This picture shows the valves flipped over on their other side. The aluminum valves I have came in one size and is supposed to replace the two sizes of the original check valve by changing the gasket sizes.

When you look inside the body of the fuel pump, you notice several things. I have not cleaned the inside of the pump yet, so you can see some debris that made it past the fuel filters. There’s also a little corrosion where the gasket is supposed to seal. The tan residue in the right chamber is also a big problem we’ve been having in the U.S. with our fuel. Allowed to evaporate, American fuel leaves this white beige residue in the fuel system which clogs the small orifices and valves inside the carburetors. This problem doesn’t affect fuel injection systems as much because they’re usually closed to the atmosphere so evaporation is less rapid, but with carburetors where the float assembly is usually vented to outside air, fuel evaporates a lot quicker. After several weeks of sitting, this residue starts to form, and the next time you start the car, the floats are stuck or the engine runs roughly.

The pump is labeled “E” for Entrata, Italian for “enter,” and “U” for “Uscire,” Italian for “exit.” I’m not sure if I’m using these verbs in the right context, but you get the gist of the letters.

Here’s a picture of the check valves installed in the pump. The left side shows the original style C/V and he right shows the replacement C/V.

Here’s a picture of the C/Vs with their respective springs. The replacement valve in the intake side (top) never sits well even with supplied collars. I’ve seen fiber gaskets supplied with some rebuild kits, but the correct rebuild kit should have Viton rubber gaskets, but they still don’t seem to seat very well. With even the slightest leak, you’ll loose pressure on the pump so the sealing of these C/Vs is crucial. The original springs also don’t mate up with the C/Vs as well as the originals sometimes causing a C/V to sit crooked.

The solutions are not so simple. I’ve heard some Ferrari shops giving up on the rebuild kits and finding viton gaskets from their own suppliers, reusing the original check valves if they’re still good. I blew on my old valves, and they seem to hold pressure, but who knows what they’re supposed to feel like! If you have to use the replacement valves, something has to be done to make the new valves seal better in the pump. Again, people have been improvising.

The other issues are in how the push lever is installed and how much the push rod in the engine moves out to actuate the pump. I’ll be showing pictures of this soon.

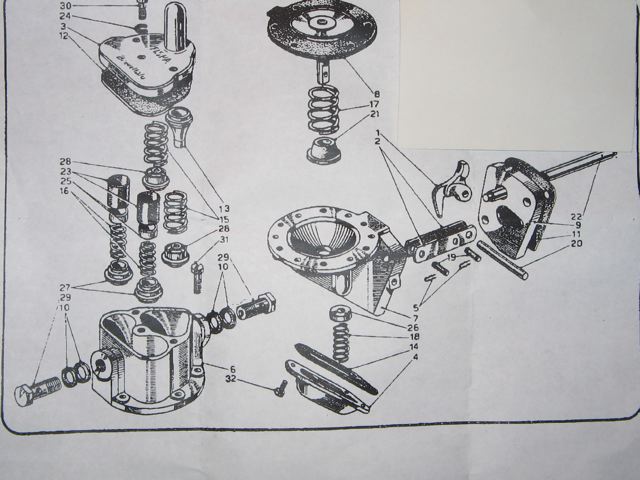

Here’s a factory diagram courtesy of Cornelis.

Cornelis also sent me a PDF file from a Lancia workshop manual. Dowload it here.

This series of pictures is trying to come up with a solution for a problem that affects several shops around the world, and I’m open to suggestions and comments on how you may have solved these problems. If the rebuild kits are no good, let’s solve the problem together so we’re not all wasting our time individually. If we can find a solution, we can affect change, saving us all time and money. I can understand some shops wanting to keep these secrets to themselves, but I believe sharing information makes the enjoyment of these cars more popular, and more people will drive these cars!

The simplest solution is to install a modern fuel pump with a regulator supplying about 5lbs of pressure to the engine, bypassing both the original electric and mechanical pumps. I have not discounted this idea, but would like to consider a fix of the original equipment.

There’s a fantastic thread about these mechanical fuel pumps on my Vintage Ferrari Forum, and if you’d like to send your suggestions, e-mail me or contribute to the thread on the forum.

Thanks everyone!

Reminder: If you’re looking for a Vintage Ferrari, or have a Vintage Ferrari for sale, please let me know. I would be happy to help you in any way that I can. I am not a broker, but occasionally hear of a good car for sale and love gettting them to the end user!

Previous Restoration Day

Next Restoration Day

Home page