330 Ignition

9/15/12

330 Ignition

Since we’re rebuilding the 330 engine, I decided to go ahead and start rebuilding the distributors for the same engine.

This job was not made easy with a set of four seized bolts that sheared off when they removed the caps. I wasn’t the one that broke off the bolts, but now I’m left with trying to get them out! I was able to grab a couple with vice grips and remove them with a little heat and patience, but a couple of them will have to get new threads installed.

Until I get the insert kit for the distributor, I decided to move on to the next project for this engine. The spark plug wires and caps were in rough shape, so I took everything apart for restoration.

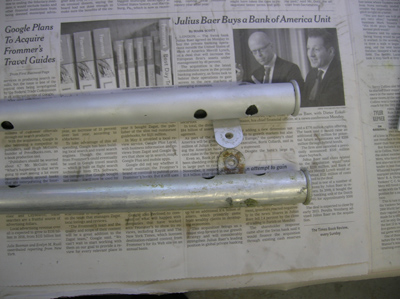

The spark plug tubes were a little beat up, but we have a tapered steel tube made up especially for straightening these pieces.

These tubes were fabricated from sheets of aluminum and gas welded together. They were then primed with a light green phosphate primer before the wrinkle paint was applied. I’ve found original tubes to often have chunks of paint flaking off because the primer did not have good adhesion to the smooth aluminum pictured in the bottom of this picture. We bead blasted the tubes before we applied a self etching primer to the aluminum to give the wrinkle paint a better chance of sticking (top tube).

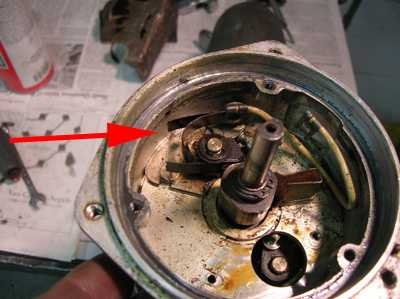

Since I was stuck waiting for a thread kit for the other distributors, I decided to start rebuilding another set sent to us for the another engine rebuild we have to do this year. When I pulled the cap off one of the distributors, it became obvious this engine was not running well when it was last parked. A spring on one of the points had broken, and was grounding out the points set. When this happens, the engine will loose all 6 cylinders on the side this distributor controlled. The car that this distributor came out of was parked and purchased as a restoration project, and this clue may have led to why the car was parked all those years ago!

The distributor bodies have are bare cast aluminum finish, but this surface gets very dirty over the years. A thorough bead blasting cleans the body well, and removes the oxidation, grease and dirt.

Inspecting the parts to this distributor, I found one lower bearing going bad, so it was removed and replaced.

Reminder: If you have a Ferrari related project, car, or idea you’d like to explore, I’d love to talk to you. I can also help if you’re thinking of buying or selling. This website represents what I love to do, and now it’s how I make a living, so if you’d like to do something together, let me know. It all begins with an e-mail!

Previous Restoration Day

Next Restoration Day

Home page