365 Tie Rods

I searched high and low for a replacement driver’s side fuel tank for the 365T 2+2 we had at the the shop and was concerned I wasn’t going to find one. During my search, I finally found a local shop willing to repair and weld the holes and broken baffles inside the original tank, but my first choice was to find a good replacement. The cost of labor to repair, and time to take and test the repairs would probably be equal to finding a new tank, not to mention another dead car in our shop taking up space while other customers patiently waited to bring their cars in!

My friend Zac in California came to the rescue with a perfect fuel tank in his parts stash he was willing to send to me. I installed it immediately on arrival, and put the old tank in storage for the inevitable day that someone will need another tank. By then the cost of repairs will probably warrant the work.

While I was waiting for the tank to arrive in the mail, I removed all the tie rods, cleaned, and painted them for the new ends to be installed.

I carefully measured the lengths of the rods so I could put the new ends back exactly to preserve the alignment specs. I really lucked out when we checked the alignment after the new tie rod ends were installed to be spot on!

While I was under the front suspension, I found the sway bar bushings to be worn and deformed. A new set was ordered and pressed into place.

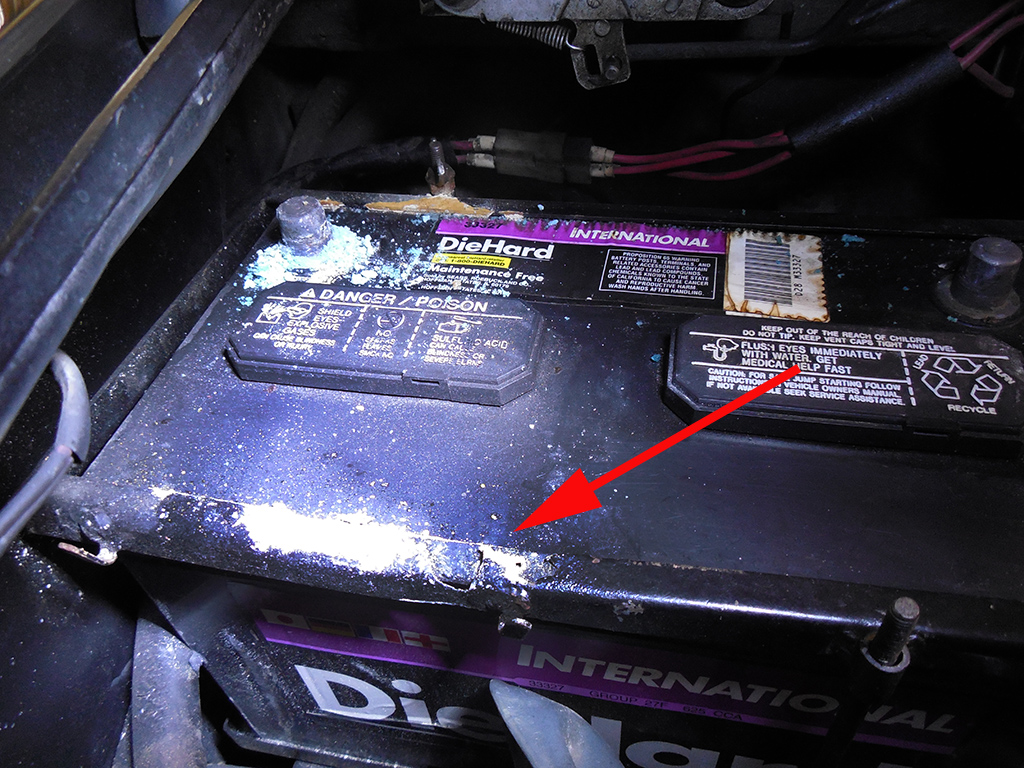

As I inspected the 365, I was looking for other any issues that needed attention, or made notes for future projects. Once area of interest was the battery hold down bracket. This area was showing some corrosion and the top battery hold down frame was pretty weak from the rust in the frame. On closer inspection, I found a previous repair was not holding up, and the best plan of attack was to remove the frame, clean it up, and re-weld the frame with new steel. This area sees a lot of corrosive gas, and eventually this bracket would have rusted through. With a repaired bracket, this car was good to go!