365 Head Removal

With the 365 engine mounted on the engine stand, I started stripping down the engine for a full rebuild.

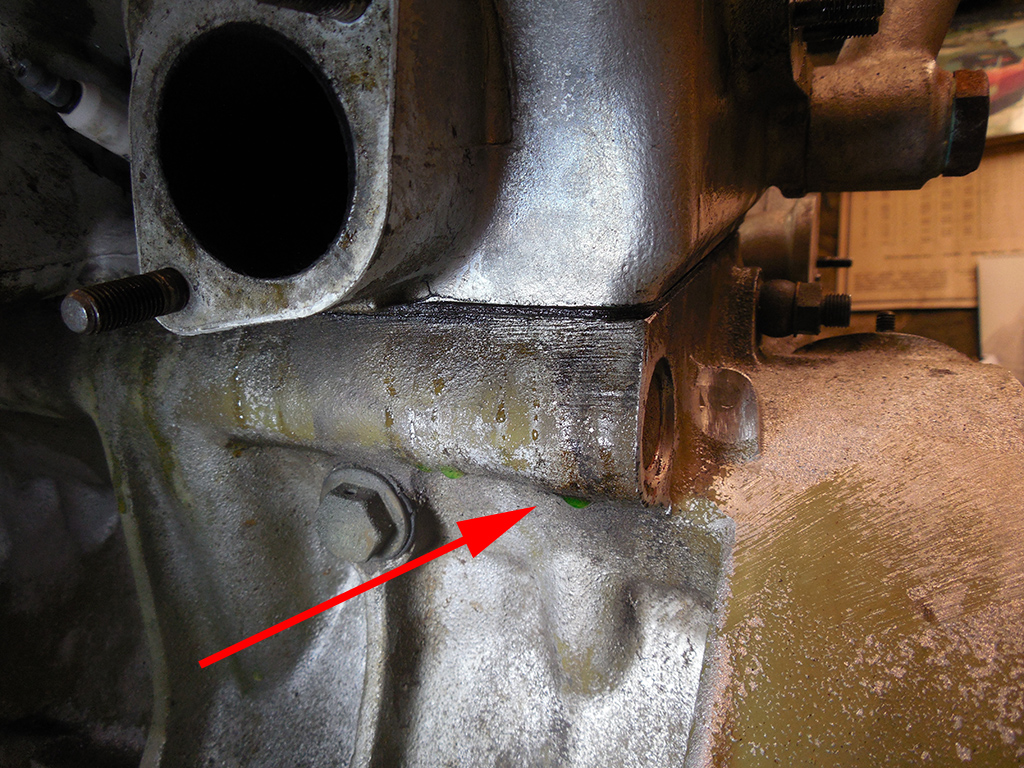

After removing the head stud nuts, I could see some signs of corrosion that would give me trouble when removing the heads. The combination of steel head studs, an aluminum block, and some corrosion from water can lock the head to the block.

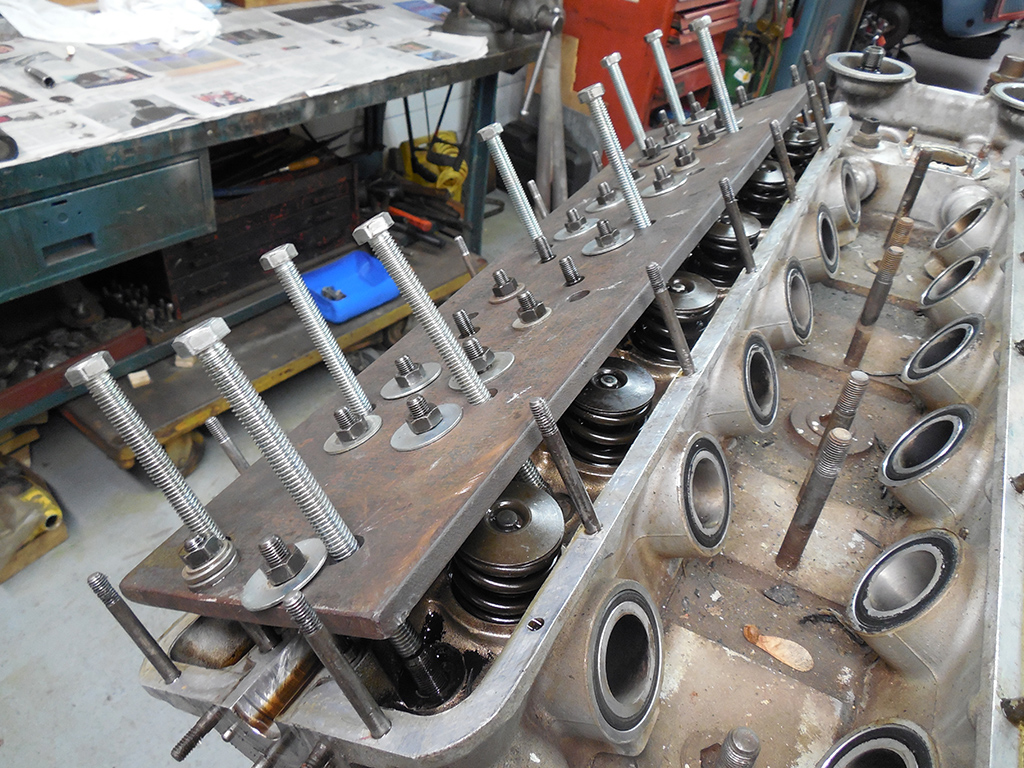

The only solution to this problem is to attach a plate to the head, and slowly apply even pressure to release the head from the block. A lot of patience, penetrating oil, and perseverance will hopefully reward you with results!

The first signs of movement will be a slight leak of coolant between the head gasket and the block.

As I applied pressure to the head plate, I looked to make sure the gap grew evenly all the way around the head. I’ve heard of many stories of impatient shops pulling, prying, and rushing this job only to crack the head in the process. Finding a replacement head, or having to weld a cracked head is a lot more expensive than taking your time to pull the head off slowly and carefully.

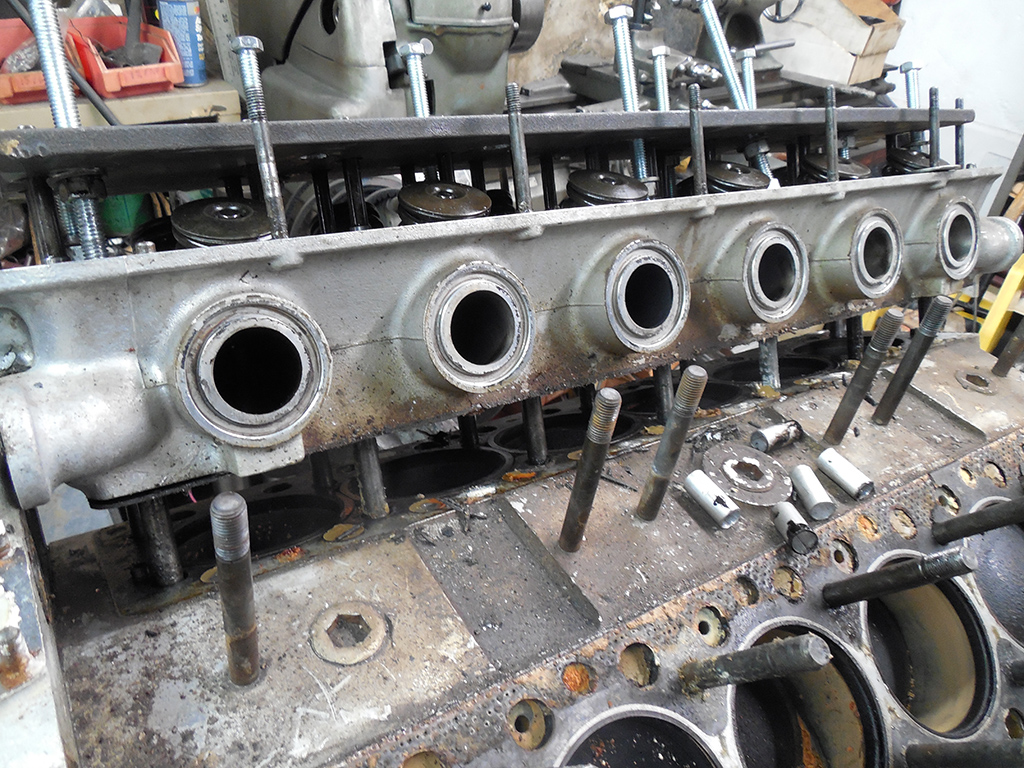

The heads eventually came off but fought me all the way up the length of the studs. The head can still crack if it cocks on the studs, so I made sure it rose on the studs evenly.

The valve covers were stripped so we could put fresh wrinkle paint back on. A little more stripping was needed though!