Tranmission Assembly

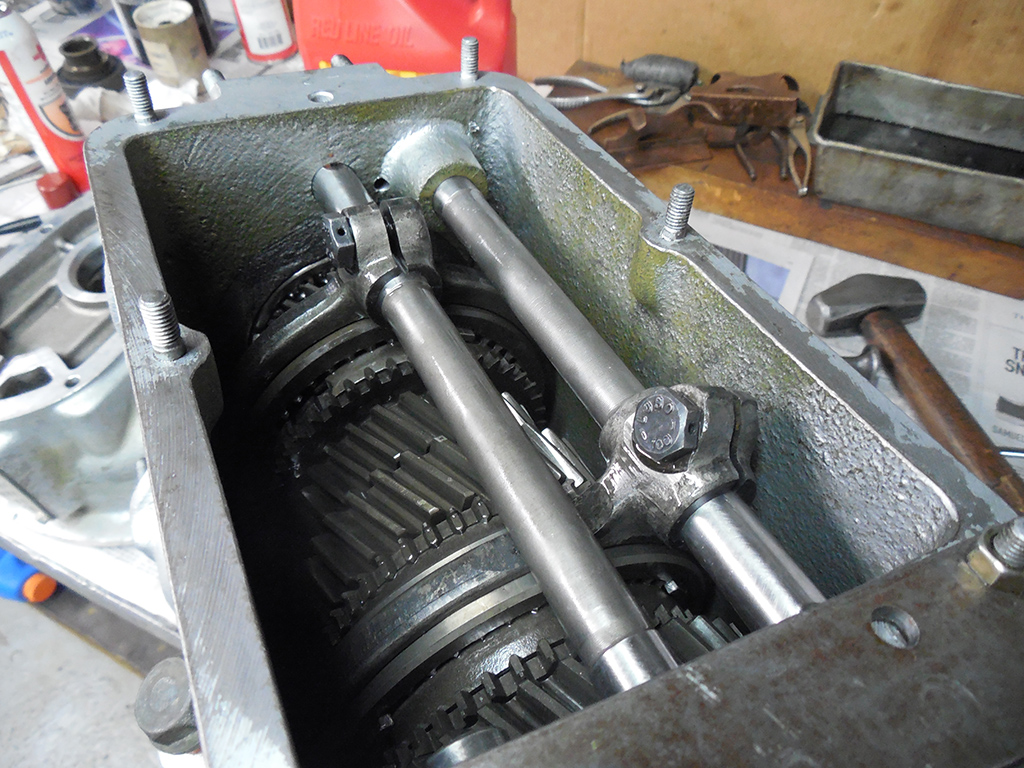

After the gears were assembled, the shift rods were cleaned, checked, and inserted into the 330 gearbox. The next step was to adjust the shift forks.

Francois had a special tool to align the shift rods and lock them in place as you checked the clearances. He found the one he had for Daytonas that was too thick to use for the 330 gearbox, but he couldn’t find the one he had for the 250/330 gearbox. Francois’ generosity often comes back to bite him when he often lends out tools to local shops never to see them again. We often forget who we lent the tool out to, so we can’t even chase them down to get them back. We’re going to have to put a stop to this!

I was put to the task of making a new tool for the 330 gearbox from something we we had at the shop. I would have loved to have made it out of steel, but a chunk of aluminum would do. I turned a disc on the lathe to the correct thickness, and cut the piece to match the other steel tool.

This process reminded me of the days when apprentices were told to make their own tools of the trade before they could work on their actual craft. Carpenter’s apprentices made their own tool boxes from wood, and I guess Ferrari apprentices make shift fork adjustment tools!

Most of the gaskets for this transmission were available, except for the bell housing gasket. It didn’t take long to make one from gasket material and a ball peen hammer.

By the end of the day, the gearbox was assembled, painted, and ready for Francois to check my work. Once he approves of my adjustments, I’ll safety wire the the shift forks in place, fill the gearbox and overdrive with oil, and put this transmission back in the car!