FIAT Dino M/C

The work continued with the Dino Spyder.

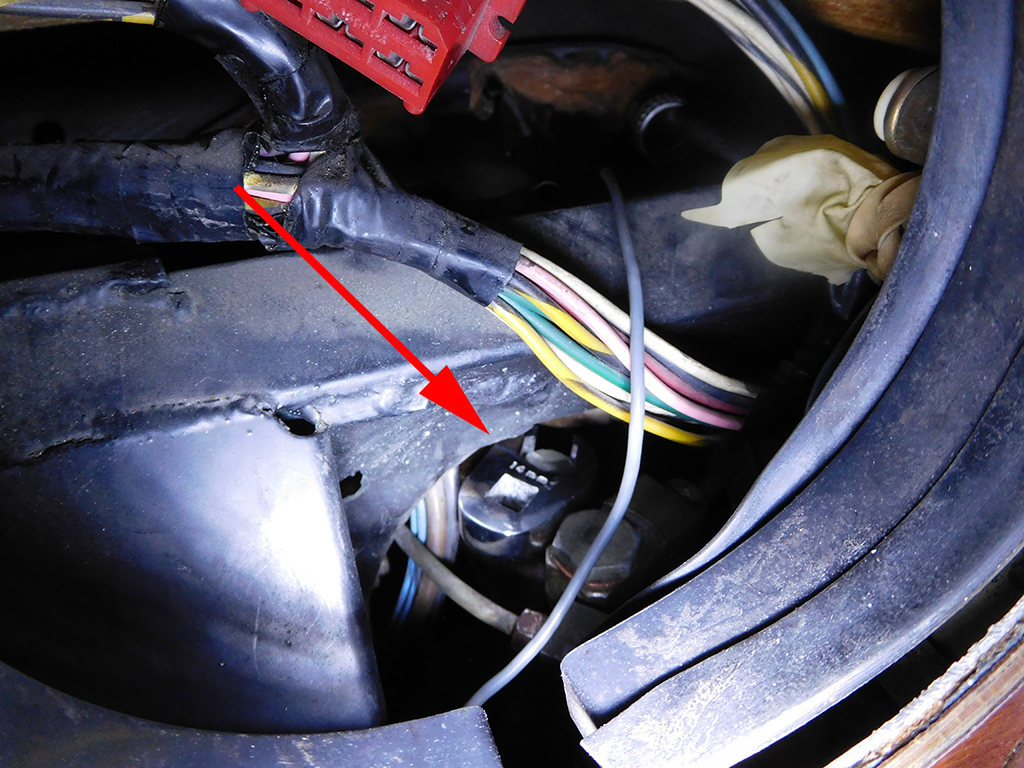

The fact that I couldn’t get the brakes to bleed properly was pointing towards the Master Cylinder. As I said last time, the FIAT M/C is mounted under the dashboard above the driver’s footwell turned 180 degrees from a “normal” brake setup. This was obviously done because there is very little room inside the engine compartment to share with the 2.4 liter V6 Ferrari engine, but it makes for a very difficult job when servicing the brake master!

With the way the M/C was plumbed, and installed, I could see this unit was probably installed before the dash was installed. There’s no way I could see a factory assembly line worker at FIAT contorting like I did to get to the fittings on this M/C!

After looking at this crazy set up, I figured the only way to access the banjo bolts at the top of the M/C was to first remove the speedometer! With only a few hundred of these Spyders around, this is the first one I’ve had to work on, and each step of the way has been a learning experience. The big lesson is whether I want to work on one of these again!

After the M/C was rebuilt, getting everything back in was even harder! It’s hard enough not to cross thread brake line and flare fittings, try doing this up side down, or reaching through the dashboard! The rear most (or foremost?) banjo bolt was nearly impossible to reach without modifying tools. Although I managed to get a crow’s foot wrench installed onto the bolt, there was no room to attach a 3/8 inch drive to the end because the dash structure was in the &*%$# way! I resorted to hammering the crow’s foot wrench with a long drift to tighten the fitting. This was ridiculous. I spent over an hour trying to figure out how to tighten two bolts. My hands were cramping, my back was aching, and my psyche was damaged. Ugh.