365GT 2+2 Transmission

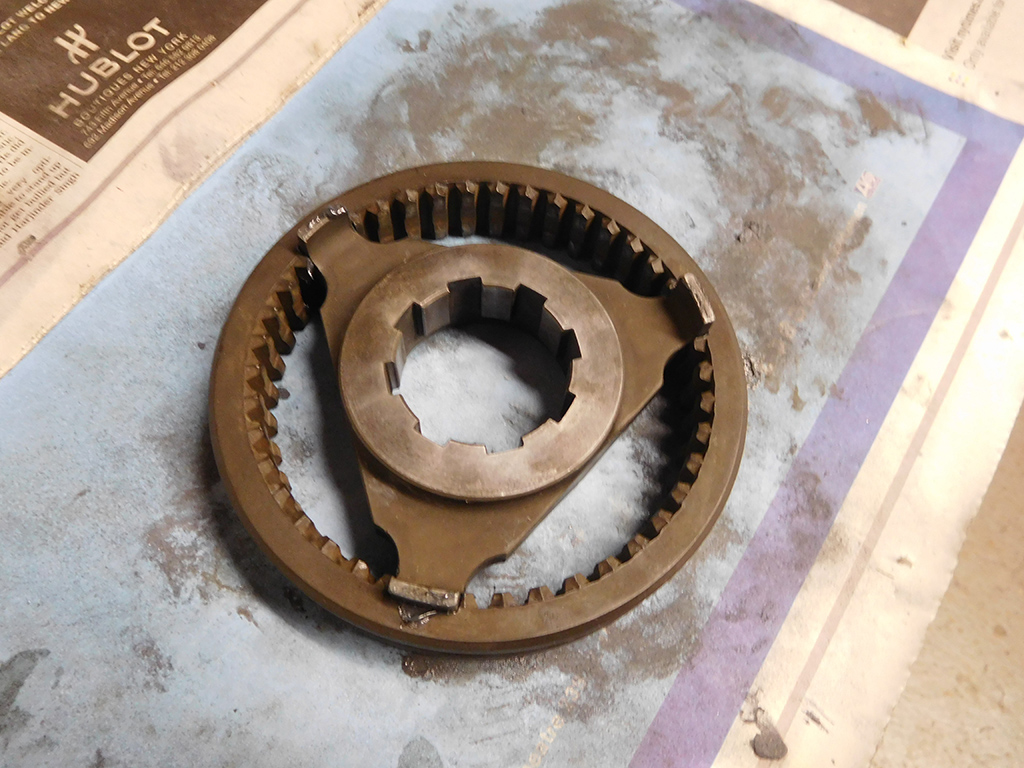

Work continued on the 365GT 2+2 Transmission rebuild. The spider gear (center piece) gets saved, but the outer dog ring gets replaced with the synchronizer ring, but this new ring can slide a little roughly along the three slots touching the spider. This movement is part of what you feel when you slide the gearshift into gear, so it’s pretty important to get this to operate smoothly. Francois had me lap the parts together with lapping compound to get this movement as smooth as possible. This takes a lot of time, lapping, cleaning, checking , lapping some more. Each part of this transmission needs to fit together smoothly, and work well together, and if time isn’t spent working these parts together now, problems will arise later!

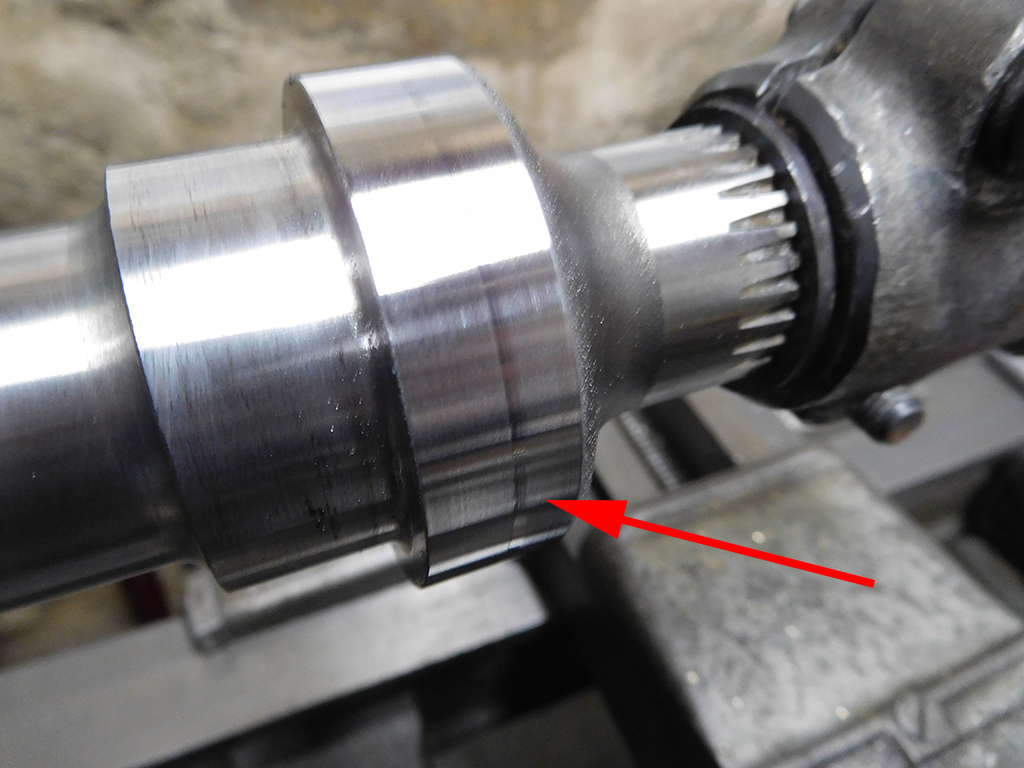

I’ve assembled a few transmissions now with Francois’ guidance, and I’m trying to remember all the tricks as fast as I can! There are no shop manuals, so it’s really about him showing me, and me writing it all down. Needless to say there are a lot of traps, like this little woodrift key that needs to be in place and checked for fit before the input shaft is installed. Small details like this, if forgotten means the whole assembly has to come apart to start again!

Each step of the assembly requires us to check the movement of the gears. There should be just enough play in all the parts to meet Francois’ satisfaction before we move on. Each time I try to feel what Francois is checking, and try to commit to memory how it should feel!

With the main part of the gearbox assembled and the shift forks installed, we checked the movement of the gear shifter. If there were any problems at this point, we would have one more chance to reverse the assembly.

The tail shaft was disassembled to replace some noisy bearings and install a new seal.

While the short tail shaft was out, I cleaned up the shaft where the oil seal contacted the shaft. A slight groove was worn on the shaft, so I polished it out a little bit. With a new seal in place, and the old groove removed, this shaft will have a better chance of keeping the gear oil sealed in place.

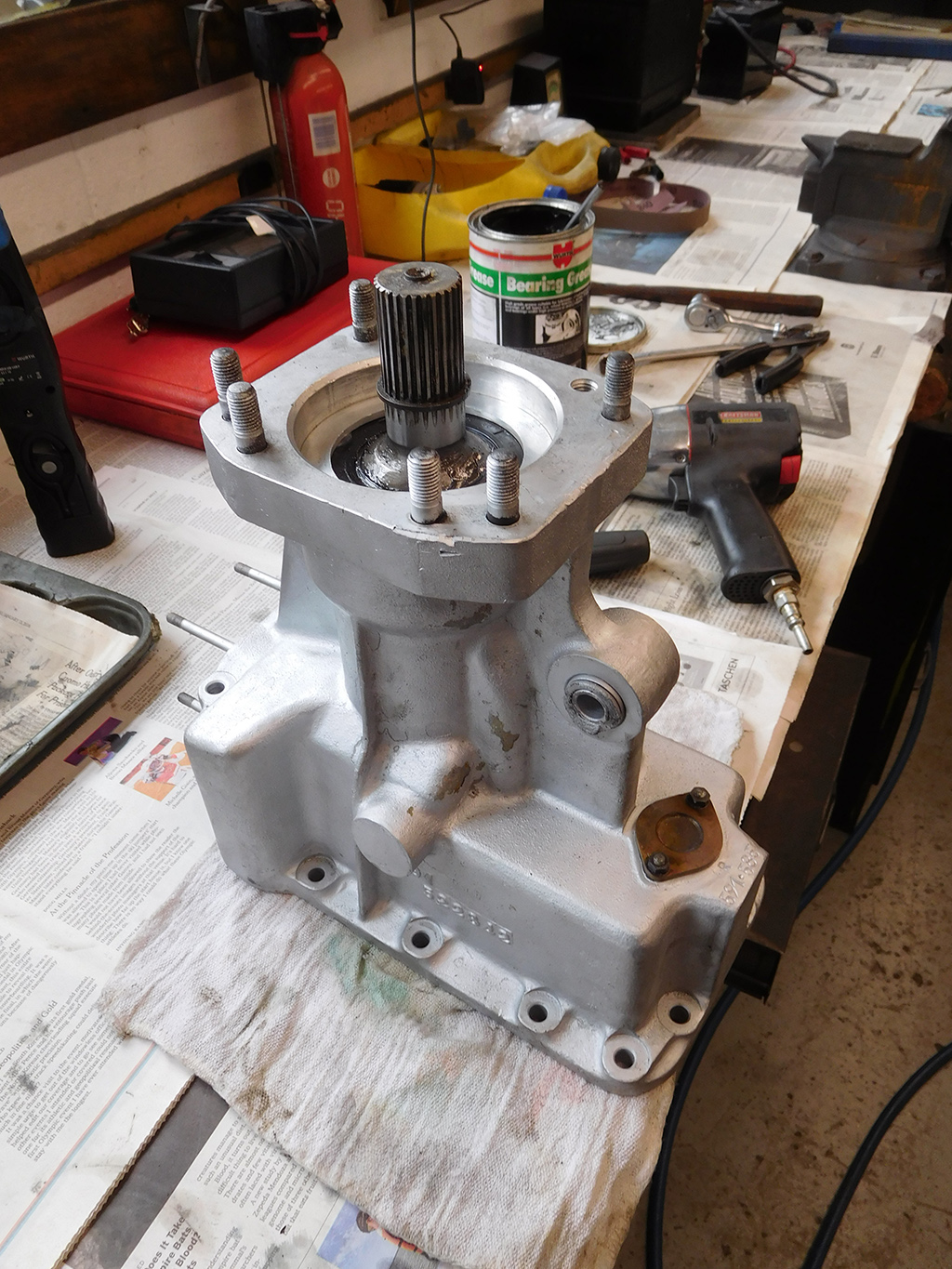

The rear section was assembled and ready to attach to the rest of the transmission. I checked the speedo gear seals, indexed the oil pump to the main shaft, and put the rest of the transmission together.

The 5 speed gear box to the 365 was now ready for installation. It’s a monster, and will take a couple of people to wrestle this into place.