Catching Up After Being Away

Having been away from the shop for two weeks on vacation, I found Francois was pretty busy! The Daytona transmission in for a rebuild has been completed, and Francois is threatening this is his last transaxle rebuild! He had a lot of problems with the reproduction parts fitting correctly, and often times fitment issues only show up when the gearbox assembly was nearly completed. The only solution was to disassemble the gear box, find the offending part, find a solution, and reassemble. Francois explained this was never how it was with gear box rebuilds. All the replacement parts went together nicely, and everything worked when assembled. Not anymore. The amount of hours it took to rebuild this transmission has not only increased, but seemed like a waste of time when the parts didn’t work. All it takes is a few thousandths of interference between parts and the transmission won’t work right.

Our next concern was how would the transmission feel when it was shifted with the reproduction parts. This test won’t be realized until the transaxle gets installed in the car and the engine is fired up. If there is a problem, we’ll have even more work to do getting everything apart again.

My bigger concern if we can’t find reproduction parts that work, then owners will have a harder time enjoying their cars, and owning a Vintage Ferrari becomes that much harder. If old Ferraris can’t be driven anymore, less people will want them, and prices may even begin to fall if the desire diminishes. There are plenty of other cars people can own, drive, and enjoy, so we need to work as a community to find solutions. If I knew where I could get consistent parts that fit and work together every time, I would get them for Francois, but where?!

I received a box full of parts and hardware for a 250 engine we’re rebuilding, so I started sorting through the hardware to send the various pieces out for plating.

The owner bought a lot of new replacement hardware, but the original plating was different than what the new hardware comes in, but we’ll send it all out for the right period plating so everything will be as it was.

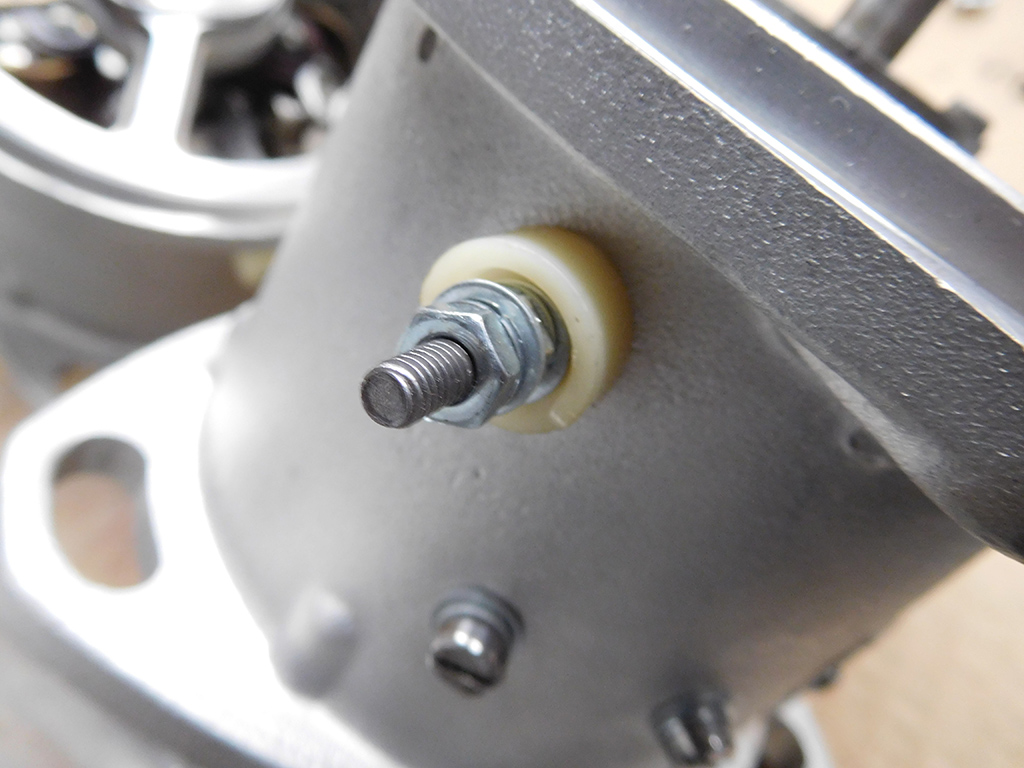

Speaking of making things right, I started the process of rebuilding the distributors on this 250 engine. The correct lug that connects the distributors to the coil looks like the one pictured above.

The insulator on the distributor I’m rebuilding looks like this. It looks like it was fabricated from scratch, and although they did a good job making a piece that would do the job, it wasn’t exactly right.

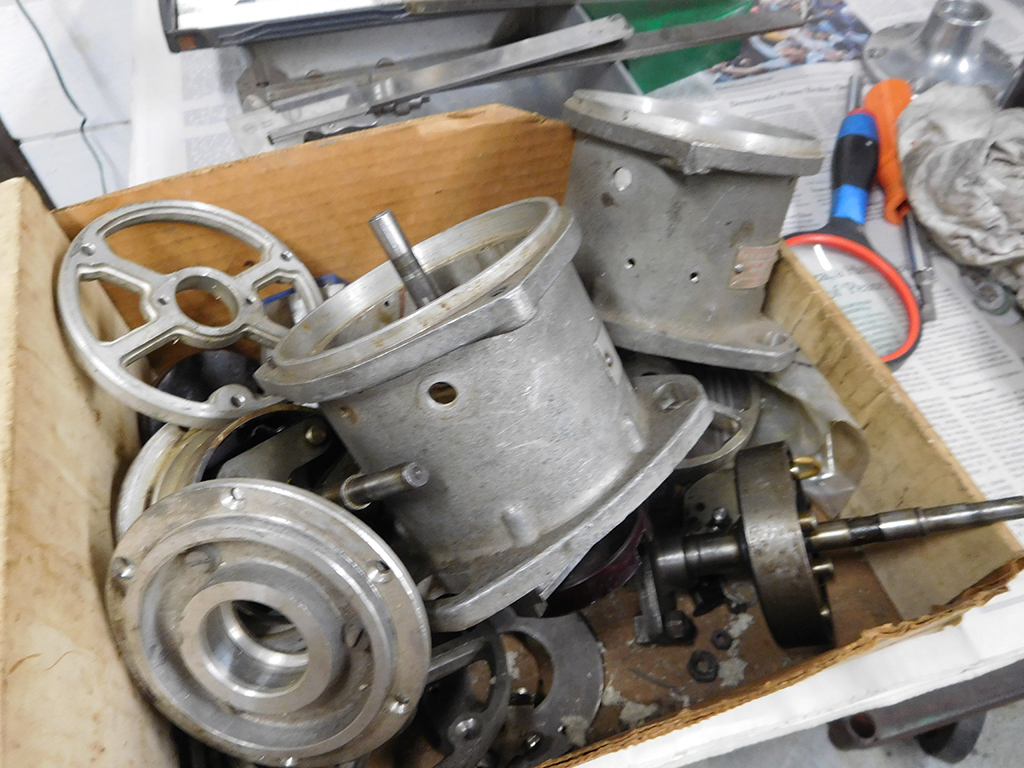

We have a box of old distributor parts that we cannibalize when we need to find hard to find parts. The common parts have already been taken, and I may have to find new source!

Each one of these insulator assemblies consists of 8 parts but three of them are specific to this assembly. I found one complete set up, and will have to search for the rest. Does anyone know if someone is reproducing these pieces? If not, they sound like a job for my rapid prototyping guy!

I started an engine installation a couple of weeks ago which we thought would go pretty quickly, but has been fighting us all the way.

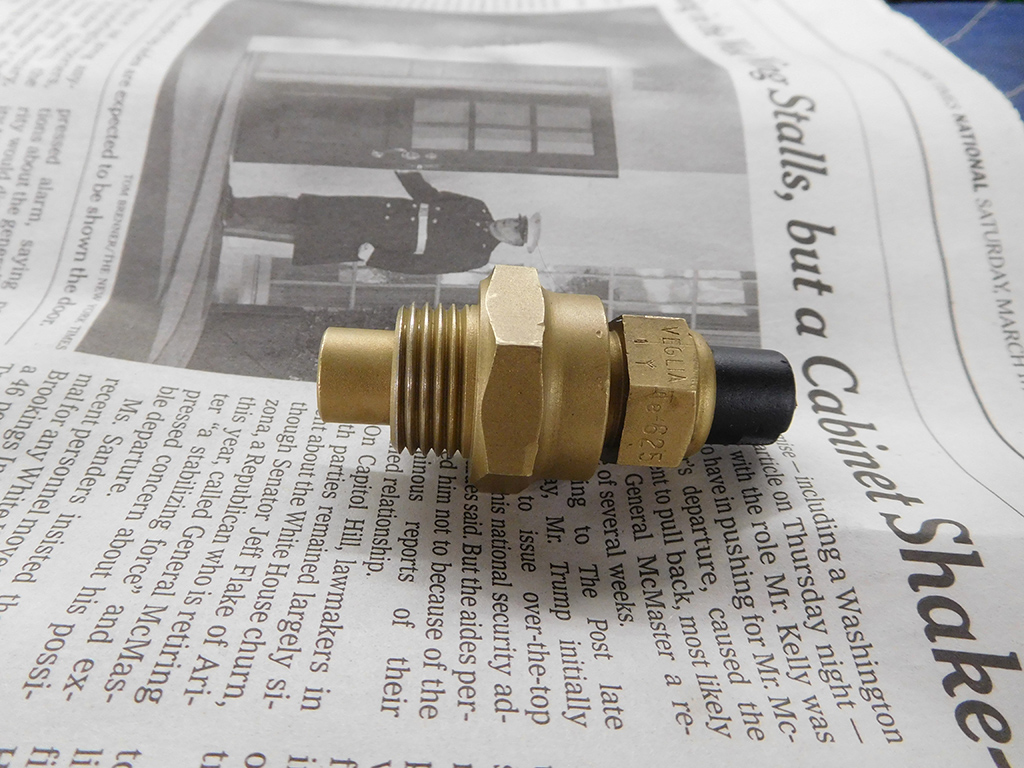

Our latest struggle was getting an oil temperature fitting on the oil pan.

As I tightened the fitting, I got that sinking feeling when aluminum threads began to pull out. Removing the fitting, I saw the evidence of what I felt when the threads pulled out.

We could retap the threads and install a thread insert, but clearance was tight considering the engine was already in the car!

On closer inspection, I could see there was plenty of thread left in the oil pan, and when you look at the Ferrari threaded adapter, it only inserted 1/3 of the way into the pan. The solution was to have our machinist make a new fitting with a deeper thread to catch more “meat” of the thread. Until this fitting is made, we wait…