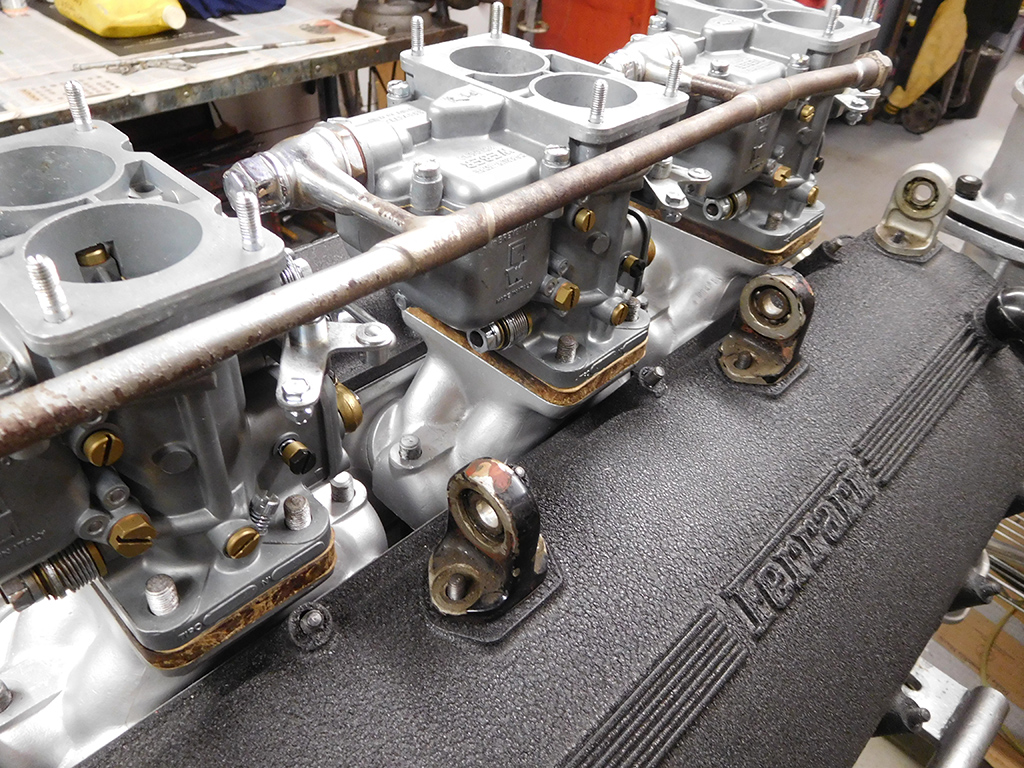

250 GTE Carburetor Details

The engine assembly is coming together nicely on a 250GTE, but the details are slowing things down just a little bit. This car came to me disassembled, and a lot of the parts to the car and the engine were thrown into a box with a lot of parts missing. Despite my best efforts to inventory all the parts, I’m still finding missing parts that I have to acquire or fabricate. Today’s task was the fuel rail and the throttle linkages.

I knew the fuel rail that came with the parts to this engine was not exactly right for a 250 engine, but was close enough to work, but I had to wait until I had the carburetors and intake manifolds installed on the assembled engine to make sure everything lined up correctly. Once I was sure everything was going to fit well, I could then send the fuel rail off the to the plater.

All the little linkages for the throttle were missing, so we had to scrounge around the shop to see what we had. Francois found enough pieces to put together a full set, but they would all need a little work.

The threaded rods were too short for our application, so I took some steel rod we had at the shop and cut new threads to make longer throttle rods.

Some of the parts had broken bolts stuck in them, so they had to drilled out and re-tapped. There was a reason why these old pieces were laying around the shop!

With new rods, I fitted them on the engine, and checked them for fit and actuation. When I was happy with all the parts, I put them in their respective batches for plating. The throttle stands will get black wrinkle paint, the throttle rods and linkages will get black oxide, and the throttle ends will get white cadmium. There was an extra step I had to make, and that was to have some of the throttle pieces stripped of incorrect chrome plating someone had done in the past before having them treated for black oxide. The devil is in the details!