Ferrari 250GTE Miscellany

I’m assembling a 250GTE at my shop and chasing down some small parts that always seems to stall the process. As I was installing the window frames, I found one of the capture nuts were missing so I had to find a replacement.

I checked the other ones, in the rest of the door, and they were still there, so I only had to fix the one.

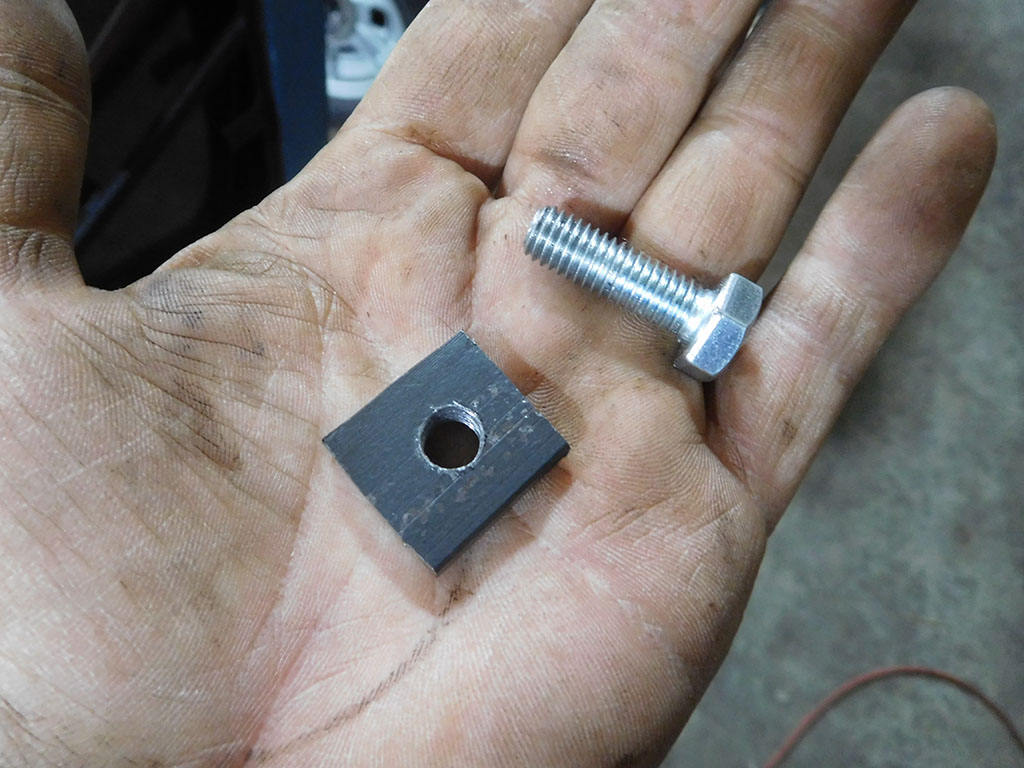

It was easier to make a square nut from bar stock than to try and find the right sized nut. Too small of a nut and it would spin free in the cage, too large and it wouldn’t fit. Custom making the nut insured it would fit and work properly.

Since I was working on the doors, I installed the door handles, but first had to clean up gaskets of the casting flash.

I finally finished the bushings for the rear leaf springs. I needed thin delrin sheets to make the end caps.

I sent a batch of brake parts and hardware out for White Cadmium plating. This type of plating is found on a lot of parts installed on Vintage Ferraris, but finding someone that does a nice job of cadmium plating has been getting tougher and tougher. One reason is the chemical used is arsenic, and is a dangerous to human health if not handled properly. The second reason is most places that do white cadmium plating are industrial plating companies that do large scale plating in large quantities. They’re often not interested in taking care of me with such a small batch of plating. Their disinterest also causes them to not take the care in making sure my parts are thoroughly plated. Through years of work with a local craftsman, I found the right balance of someone who doesn’t mind running small batches, and cares about the quality. It may cost a little more, but the results are worth it.