Ferrari 365GT 2+2 Oil Leaks

It’s been a tough few weeks for everyone in the world with the Covid 19 Pandemic. New York, where I live, has asked everyone to stay in place to limit the spread of the virus, and I’ve been trying my best to follow these orders. Since I work by myself most of the time, I have been spending my time at the shop working on some cars. I am lucky to have this distraction, but hope everyone else is OK, and staying safe.

A Ferrari 365GT 2+2 that I’ve been taking care of through three owners is in for it’s annual service. The current owner has owned the car for several years, and hopes to use this car even more once this “shelter in place” order is lifted.

One of the items on my list of to-dos was to assess some of the oil leaks and decide which ones were pressing and which ones could wait. I saw there were some minor oil leaks from the valve cover gaskets, but since the car was not due for a valve adjustment, I felt this could be addressed next time. I did notice, however, a lot of oil dripping from the front of the engine that wasn’t there last year. Closer inspection found the source of the oil was coming from the front pulley seal. Oil was leaking past the seal, and being slung by the pulley all over the front of the engine.

This seal was behind the front crank pulley and needed access for an impact gun to remove the nut that retained the pulley. This access required the hood removed, cooling system drained, A/C disconnected, and radiator removed.

In times of social distancing, I didn’t want to call my local friend to help pull the radiator, so I set up my engine crane to ease the radiator out of the car. With everything disconnected, it still required some finesse to get the radiator past the cooling fans, hoses, and alternators, and in times like these, my engine crane was my extra set of hands.

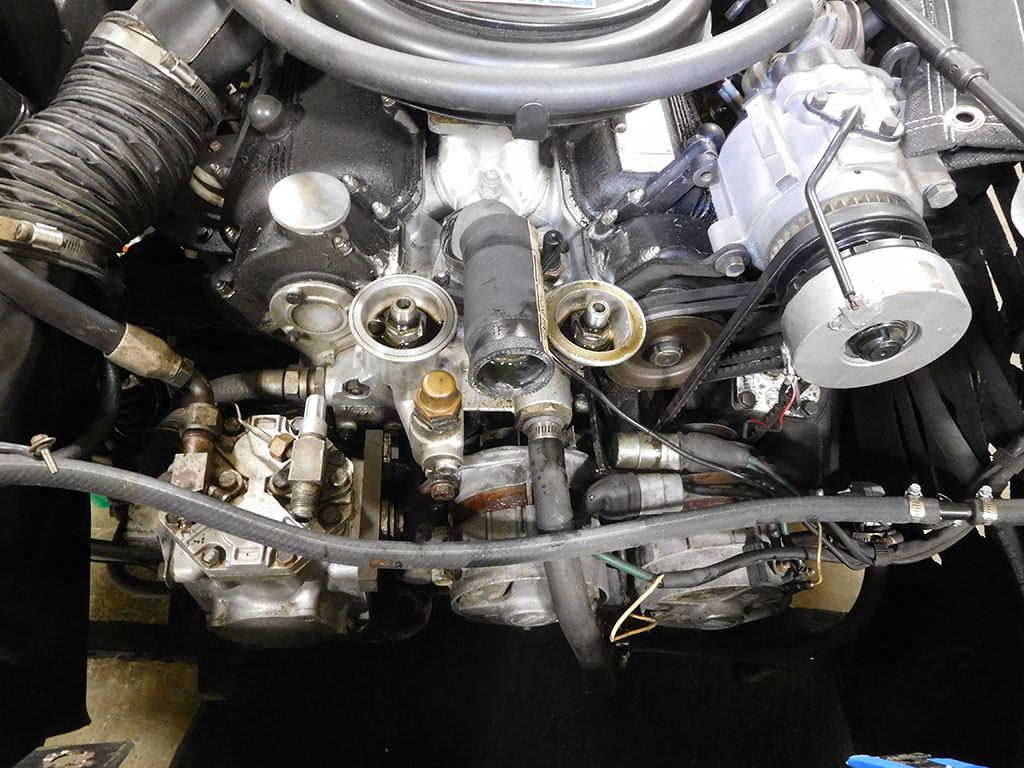

Even with the radiator out of the way for crank pulley access, I still needed to take the belts off of the pulley which offered its own set of challenges. There are a bunch of drive belts on this car and they all seem to be interconnected. Ferrari also does a funny thing by turning a lot of accessories around to face toward the engine so the pulleys are closer to the engine. This helps with compact packaging, but is horrible for servicing! The crank pulley drives the A/C and two alternators, but the air pump pulley had to removed first before tension from the alternator could be loosened. The A/C compressor had to practically be removed to loosen these belts. Trust me, it was a pain in the butt!

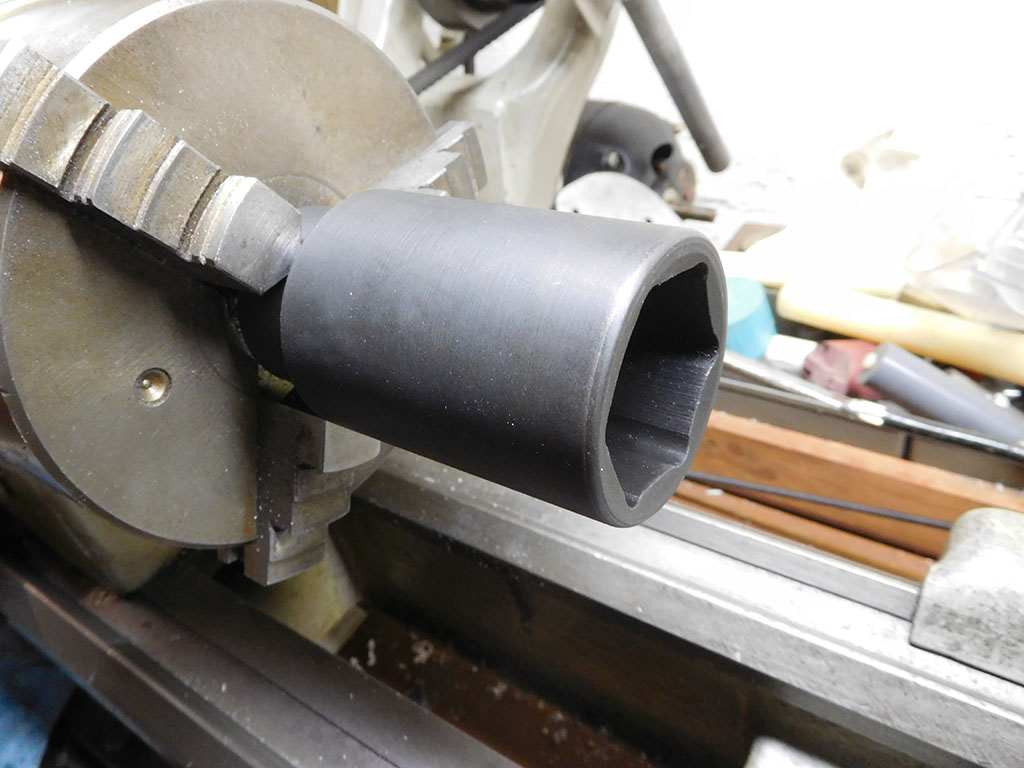

The other challenge is getting the 36mm nut off the crank snout. Ferrari uses a very narrow crank pulley, and a regular socket will not fit down inside the pulley to remove the nut. You get one shot at removing this nut because if you round off the edges of this nut, good luck getting it off the car.

Normally, I would head down to my mentor’s shop and borrow Francois’ special impact socket made for this procedure, but I wanted to keep my distance from the octogenarian during this Pandemic. The solution was to buy my own socket and turn it down to size.

The chrome-moly chips were hot coming off my cutter, but I didn’t have to remove much to get the socket to fit down inside the crank pulley. It might not have been a lot, but impossible to do it without. Now I have my own special tool for the next time I need to remove another nut. I figure it’ll probably be in a few years!

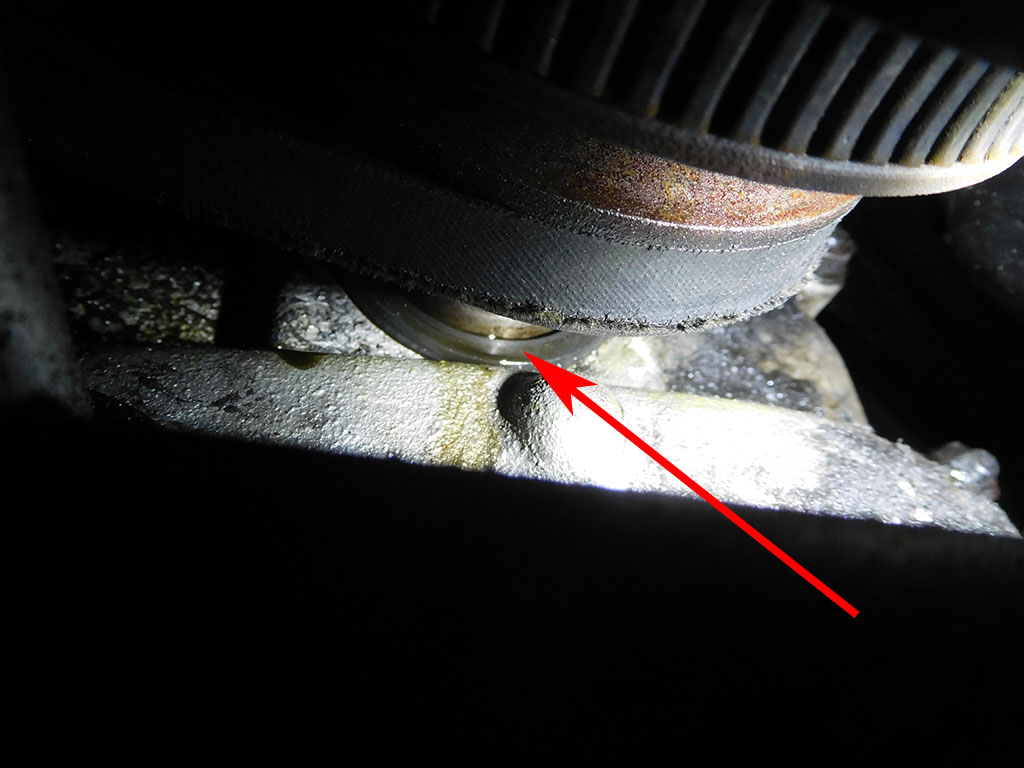

With the nut removed, and the pulley out of the way, I finally got access to the seal. It was rock hard and slightly out of position, so that was the reason for the leak. You can see how the bottom of the engine was cleaner from the fresh oil running down, while the rest of area was covered in dirt stuck to the oil slung around from the oil leaking onto the crank pulley. I’ve got some cleaning to do before everything is put back.

The nice thing about inspecting areas of the engine that has very little access is I can try to spot potential problems. The lower radiator hose was cracked and one step away from bursting. I’m sure being exposed to oil from the crank seal leak didn’t help preserve the rubber.

Even though we’re going to save the valve cover leaks for next time, I decided to address the right side distributor leak. The transmission was rebuilt on this car about 2 years ago, and I could see fresh oil running down the bell housing. Luckily, the right distributor had easy to access, and the left side was bone dry.

Another catch when disconnecting the parts to the right distributor was corrosion on the ground strap. Acid vapors from the battery tend to settle on surfaces around the battery and corrode. This white powder was collecting the ground strap to the engine. Luckily I caught this before the acid ate through the cable. I’ll neutralize it with some baking soda to stop the corrosion.