Ferrari 330GTC Bumper Repair

The rear bumper section came back from Ryan at Brightworks in Ohio and the repair looks great.

A month ago, I was asked to repair a crack on a bumper on a 330GTC. From the outside, it looked like a small crack in the plating, but I knew it was going to be worse when we looked closer.

I took the bumper to my local plater, whom I trust and does very good work, to see if he could fix the problem, and he brought the bumper back to me after he stripped the chrome from the bumper. The crack was forming from rust between the outer layer of the bumper and the support bracket behind. The rust was swelling and forcing the two pieces apart, even popping the welds the factory made years ago.

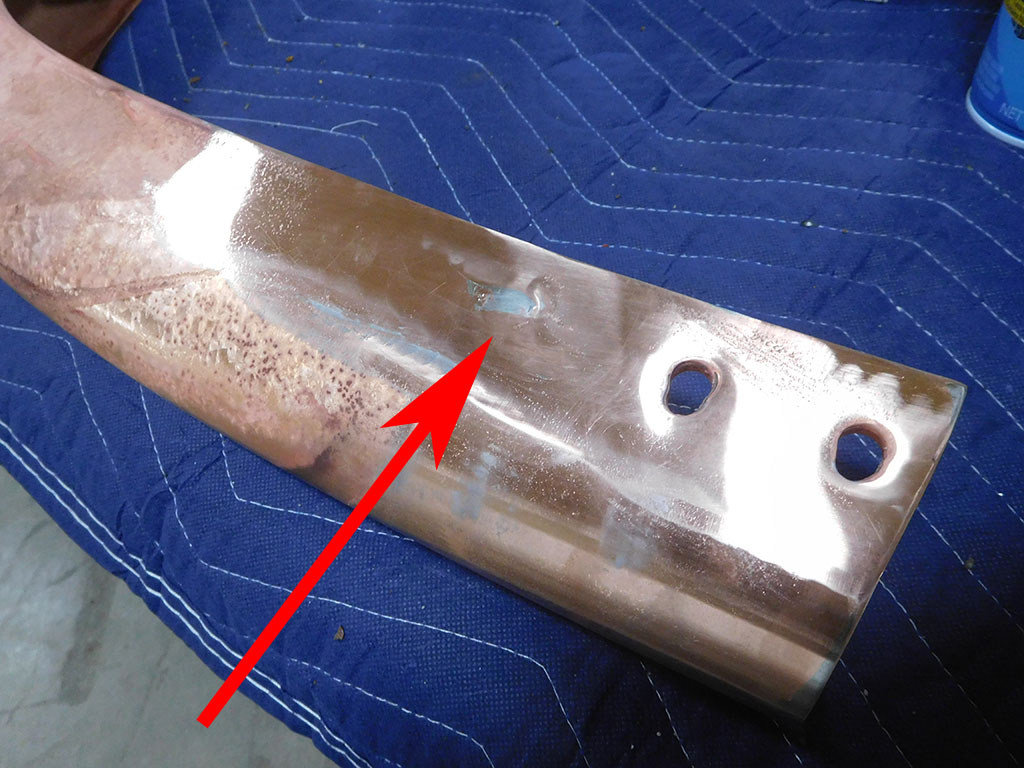

Grinding back the copper layer of the plating, we could see the steel section getting pretty thin, and a previous plater chose to file and smooth this imperfection and cover it with copper and more plating. My plater admitted that if we did the same thing, this repair wouldn’t last long either. The solution was to cut back the outer covering, remove the rust, fabricate a new outer surface, weld it in place, grind and polish smooth, and plate the bumper. My local plater also admitted this repair was perhaps beyond his skill sets and I appreciated his candor.

I called Ryan Filburn of Brightworks in Ohio. They do some of the country’s high end chrome plating on cars that actually end up at Pebble Beach. Many people use the term “Pebble Beach Restoration” but never really understand what that means, or have actually seen a Pebble Beach level car. Brightworks actually has been involved with the chrome on a dozen Pebble Beach restorations, so they know what they’re doing. Ryan personally repaired this bumper for me, and you cannot see where the new section was welded in place.

Ryan even sent the old piece with my bumper to prove how bad it was. That little crack in the chrome was actually a paper thin piece of steel rusting away under the chrome plating.

The support structure behind the bumper had all its rust removed, cleaned up, and welded. A nice layer of plating was applied, and we’re good as new, maybe even better. There were a lot of hours of work to get to this level of quality, but was well worth it. Considering the owner trusted a another shop to plate his bumper where it was poorly repaired and cracked only a couple years later, doing it right the first time would have saved him money and time. Sometimes, however, this is not the fault of the owner. I always say, every vendor tells you they do a great job. What vendor tells you they do mediocre or crap work?! The only way to know is with references and examples of their work.

Thanks Ryan for your time and skill!