Dino Cooling System and Chrome

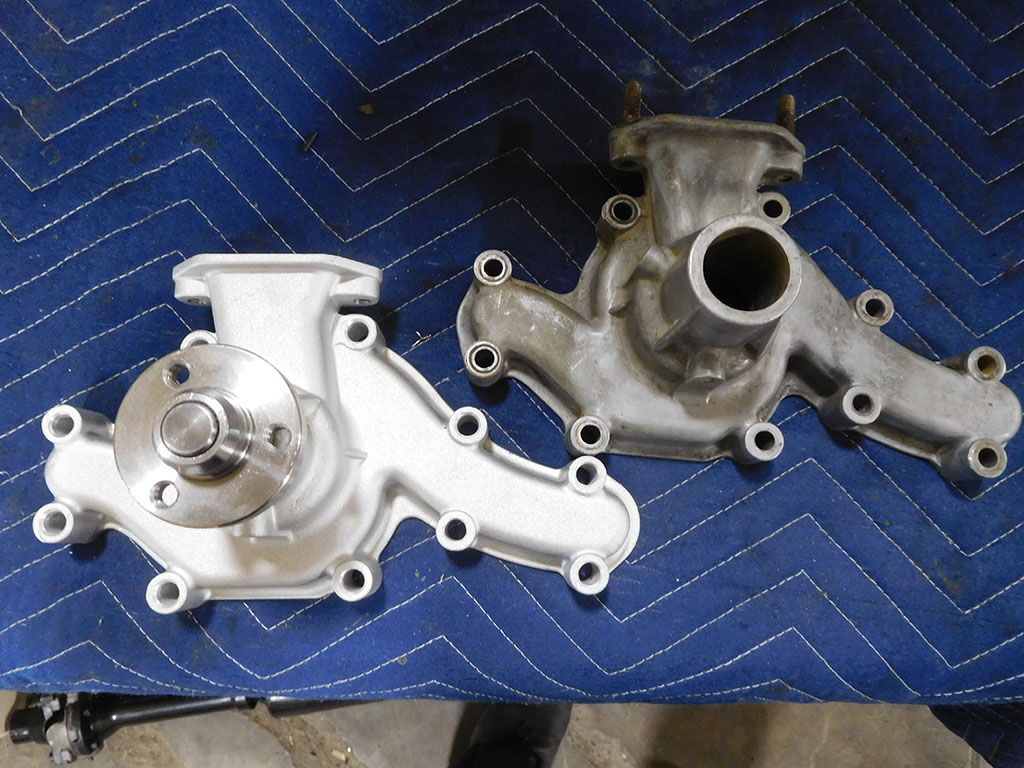

I’ve been waiting for a new water pump to arrive for one of the Dinos I have at the shop, and it finally came. The sand casting is different from the die cast original one, but it at least does not have a hole in the case!

The original one had developed a small pinhole from corrosion.

Before installing the new water pump, I scraped off the scale and corrosion on the block.

As I disassembled the cooling system, I found more pipes showing corrosion. The thermostat housing was getting eaten away so I ordered a replacement. Its casting is similar to the new water pump unit, but the function will be better than the old one! All this corrosion was probably from coolant going bad and sitting stagnant in an engine that doesn’t see a lot of mileage. As the corrosion inhibitors fail in the antifreeze, the coolant turns acidic, and starts to eat away at the metal. Because of the different metals in the cooling system, galvanic corrosion can play into effect.

I think the thermostat housing corroded much more than the water pump because coolant would only circulate near the thermostat when the thermostat opened. Allowing the engine to warm up, circulating the coolant throughout the system, and regular coolant changes would have lessened this damage. Simply put, Drive the Cars!

I saw the main cooling hose that ran through the center of the car was probably original and over 40 years old. This car is a well preserved very low mileage original car, so it’s very possible some of this rubber is original. I wanted to be safe and replace these hoses to prevent a disaster from happening.

Ferrari ran rubber hose through a center chassis tube that is the shape of an oval, and there is just enough room to slide two hoses through this oval shaped opening. I would have considered buying regular cooling hose for the replacement, but the fit of this hose was crucial, so I paid the “Ferrari Tax” and bought Dino specific hose to avoid problems with fit.

The damage from the corrosion of the cooling system continued with another bad water pipe.

I sent the bolts to the the wheels out for plating. The cheap and easy fix a previous shop did by plating over the bolts didn’t last very long, and was dangerous when the thin razor like sheets of chrome plating started flaking off.

My plater spent the time removing all the old plating, polished the steel, and reapplied new layers of plating.

I also sent out these bumper caps from the rear bumper out for plating. The insides of these caps were rusting, and was a bit of an eyesore.

The newly plated caps look great and my plater followed my instructions not to polish the insides of the caps so they would look like the original finish.