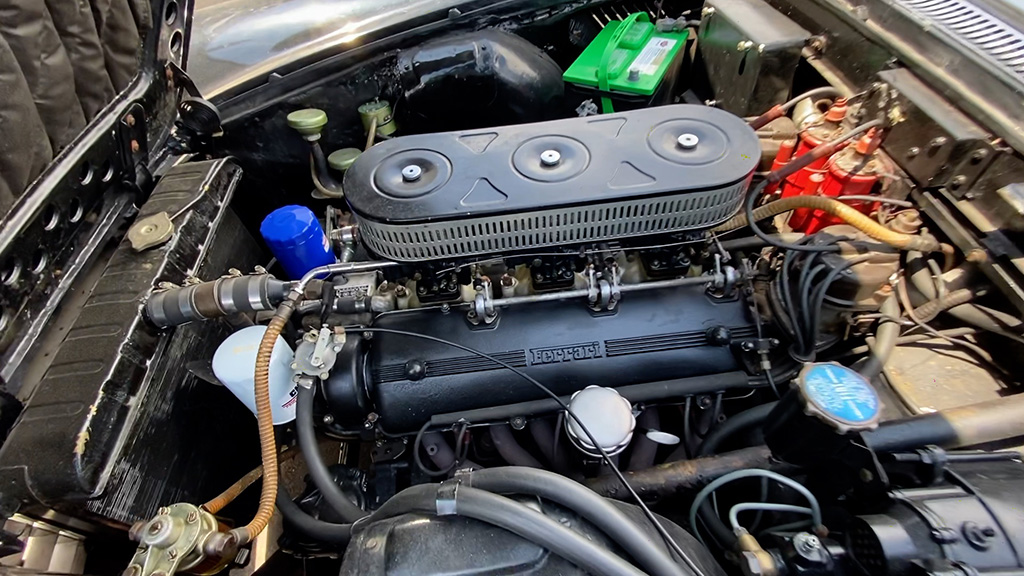

Ferrari 250GTE Floorpan Repairs

This past Summer, a Ferrari 250GTE owner dropped off his car at The Panel Shop in Stratford CT for some floor pan work.

This car has been owned by the same owner since the late 70s, and has amassed quite a bit of memories for the owner and his wife. The car has a lot of original details, so it has managed to survive through the years without losing parts.

The interior was replaced a decade or so ago, but has the incorrect carpets.

The reason the car was brought to Mark was because after a new exhaust was installed, the clearances seemed off. The previous repairs to the floorpan done before the owner bought the car in the 70s brought the level of the floor too low for the exhaust to fit and it was time to take a closer look.

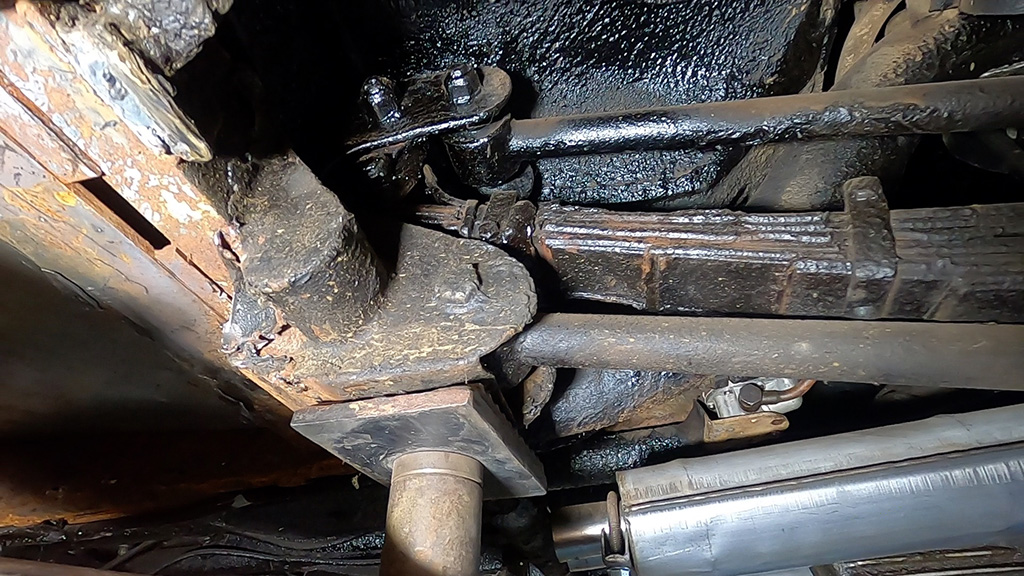

After Mark removed a crudely welded bottom layer of floorpan, he was shocked at what he found. The previous shop braced pieces of angle iron and flat bar stock between the frame rails and what was left of the original rockers. Some pieces were barely welded to the substructure offering very little support.

Although the replacement steel was plenty strong to hold up the floor, it’s strength was negated by the way it was attached to the original structure. A lot of bracing was simply floating in mid air, supported by the sheetmetal that it was supposed to hold up!

The original Ferrari rockers were somewhat corroded but the inner dimple dyed panel was still there and may be saved. Look at how the I-beam shaped piece on the right side of the picture was simply jammed into the place with very little support from the original structure.

The poor work continued on towards the back with little improvement to the effort.

The rust looks like it continued into some of the rear suspension structure and the previous shop tried to weld new metal to it. Hopefully when all this bad work is cut out, we will still have enough original structure to rebuild and reinforce.

This was probably the worst repair I’ve seen to a floor pan yet. I don’t have a problem with shops doing floor pan work where they get the original details wrong, like the bead rolled patterns or the dimple dyed panels, but these panels were barely safe! The Steel they chose to use for these repairs was a lot heavier than the original pieces, but the added weight didn’t add any strength to the original design. In fact, the way it was welded in place, it was probably weaker!

I shot a video going over the details on this original car, and the floorpan repairs. Stay tuned to follow the work on this car in future videos and blog posts!