Dino Brakes

I found the parking brake on the Dino was out of adjustment, and soon found a stuck piston and worn brake pad. To free up the one piston, I needed to remove the caliper, so while everything was apart, I might as well rebuild it. I’m trying not to refresh everything, as it’s a slippery slope towards restoration, but I’m still replacing seals, and pistons.

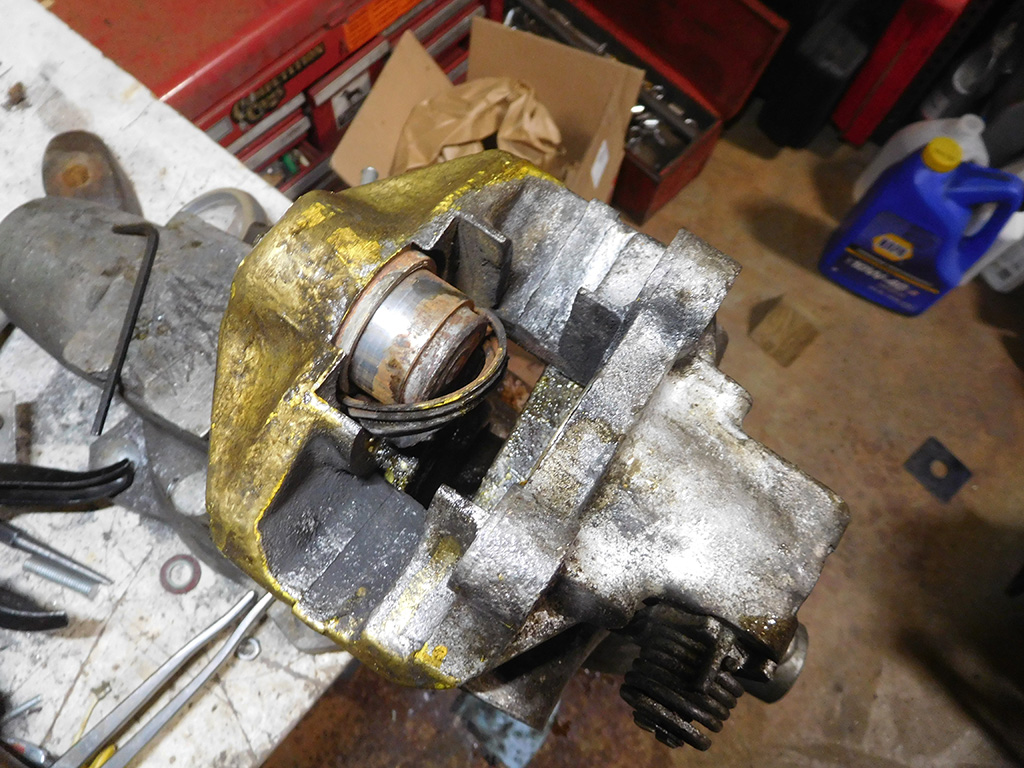

The original pistons were chrome plated steel units that can pit and rust. These pistons were in decent shape, but showed a rust ring that was the cause of the seizing. With replacement stainless steel pistons it was cheap insurance to help eliminate one issue with seized brakes.

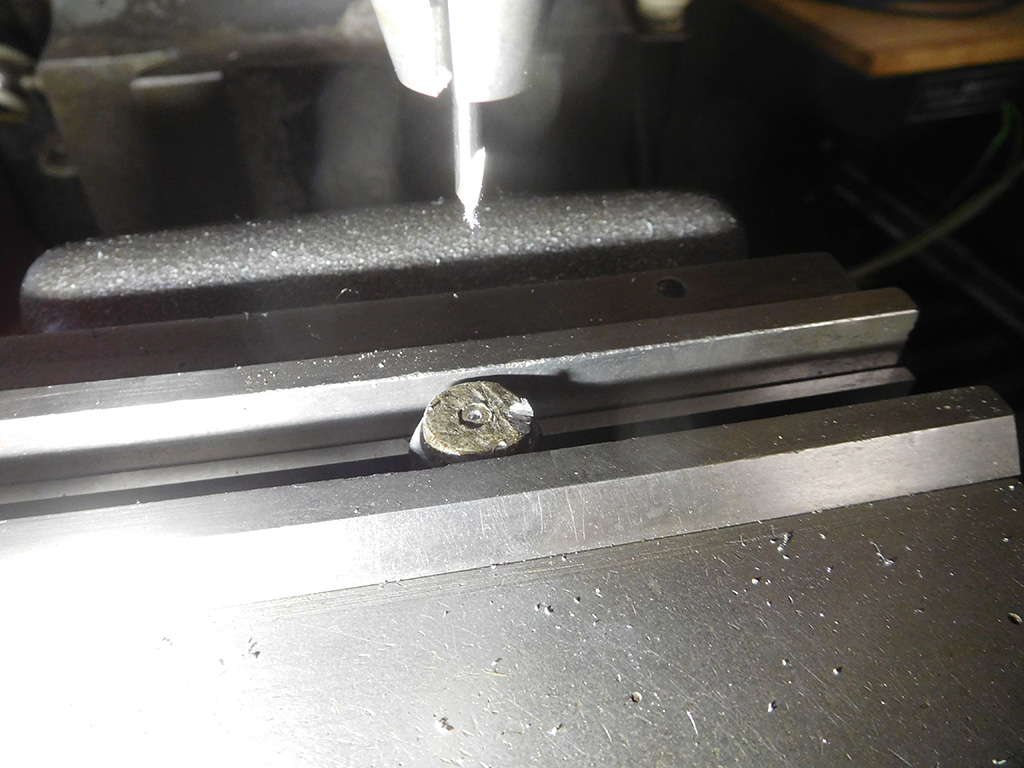

Whenever brakes are serviced, there is always a challenge, whether it’s from a snapped bleeder screw to a seized brake line. This Dino had a sheared allen key inside the parking brake adjuster cap. If I couldn’t remove this cap, I wouldn’t have been able to withdraw the brake pads. I first applied some heat with a torch to break the rust holding the screw in place, then I used a chisel on the edge of the cap to remove it from the caliper. With the cap removed, I would continue with the brake rebuild, but I still had a sheared allen bolt to deal with. I looked at the listings on the Dino websites, and this part didn’t look readily available, so I would try to drill out the allen key.

Allen keys are supposed to be made out of hardened steel, so drilling it out would present some challenges. Even if I managed to drill a hole in the center of the stuck allen key, the use of an “easy out” wouldn’t work because the shape of the hexagonal allen key wouldn’t allow the “easy out” to turn. All these possibilities and challenges were going through my mind as I tried to decide how to proceed. I decided to first try to drill the center of the sheared head with a centering drill on my Bridgeport. I was surprised how soft the material was when I started the hole. Once I had eyeballed the center and started the hole, I increased the hole just short of the allen key edges. I realized that the reason this allen originally sheared inside this hole so easily was because they must have used a cheap allen key that was made out of mild steel without any hardening. An Ikea allen key that you get with flat pack furniture comes to mind!

After drilling a hole to the edge of the broken allen key, I took a sharp pick and chipped the edges that were left in the hole, eventually getting all the broken pieces out. I managed to save the cap, and even the hole for an allen key! I’ll be using a proper hardened allen key when it goes back together!

The previous owner thought it would be stylish to paint the caliper on this Dino with yellow caliper paint. With some time, brake dust, and road grime, the yellow paint has turned into a sickly green color. I will try my best to remove this paint and do something a little nicer and more fitting a Dino. I believe the original finish was white cadmium, but in order to re-plate these caliper bodies, they would need to be completely disassembled before sending out for plating, a little too involved for this particular job!