Making 330GTCs Safe

I had a new customer contact me regarding a 330GTC he recently purchased and asked if I was available to go over the car. We had a discussion about what his expectations were with the car and how he planned to use it. Some guys want to show their cars, some guys want to drive them, and each owner is different. I have to modify my work to fit the customer, and also decide if it’s work that I want to do. As much as customers are learning about how I work, I have to decide if I want to do business with them. It’s all a learning process.

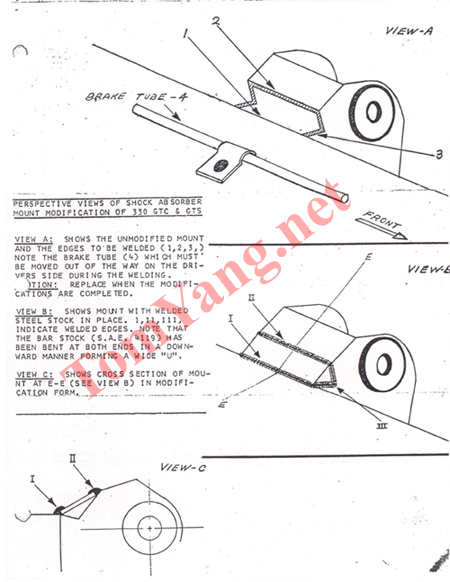

The first thing I check on any 330GTC is whether the suspension mounts have been updated. This is one repair I will not avoid. In fact I called the customer immediately and told them I would not road test the car until this repair was made. I already removed the paint from the area supporting the shock and spring area, but you can see the whole font suspension on GTCs is supported by this loop of steel with a large gap you could put your fingers through. Ferrari released a recall letter back in 1970 to advise owners to have this design repaired to avoid catastrophic failure of the front suspension. The two page letter is attached below.

I am always surprised when I find another GTC that has not been repaired and often wonder how a car being serviced by so many Ferrari shops through the years managed to escape this update. I have talked about this issue for years, and have tried my best through the Internet to spread the word, and yet here we are.

The worst part about a failure is how dangerous it can be if the left shock mount were to break. I removed the steering coupler and u-joint to give better access to my welder, but you can imagine if this poorly designed shock mount breaks, the shock and spring assembly would collapse into the steering shaft and lock the steering control. Rumor was there was actually a death attributed to this failure prompting the recall letter you saw above.

It’s actually a very simple repair that doesn’t require a lot of disassembly. Boxing in this area will strengthen the support of the suspension immensely so I got got to work prepping the area and fabricating some steel to fit in the gap.

The right side had great access to fit a spacer, so I removed the paint on the chassis and readied the area for welding.

I covered the area with a fiberglass blanket to avoid welding splatter from igniting any fuel or oil and had several fire extinguishers at the ready, but quickly welded everything up. Having done this repair, I felt a lot safer driving the car, knowing the front suspension wouldn’t break! Now I could take a look at the rest of the car.