More Mondial please

-

John Vardanian

- Posts: 1908

- Joined: Wed Sep 04, 2002 12:13 am

- Location: San Francisco Area

More Mondial please

I would love to see more about the Mondial rebuild.

Bryan P, those mouse trap springs, are they NOS or were you able to source good modern replacements?

john

Bryan P, those mouse trap springs, are they NOS or were you able to source good modern replacements?

john

PF Coupe

John - the mousetrap springs are the same ones that have been in the car since at least 1960. Since each spring is actually two springs joined in the middle, if there is a break somewhere in a coil, you still have the action of 3 springs working on the valve - doubly redundant!

The three of us stood defeated staring at the damned thing after trying to muscle the springs for 3+ hours a few weeks ago. We then designed the door hinge tool you see in Tom's entry because the Lampredi tool (which is also in the photograph) is only really useful once the two springs have already been depressed 80% of the way, or on much lighter springs that you find on the v-12. We also had to fabricate a base for the Lampredi depressor we borrowed from David Carte, since its base is designed for the stud spacing on a v/12.

Before our tool was fabricated, dad called all the various luminary Ferrari vintage motor people in this country and overseas to see if anyone else had already fabricated such a tool - it appears that many who actually run their Lampredi fours converted to coil springs quite awhile ago! So if we ever break one of our mousetraps, we know who to call for spares!

The three of us stood defeated staring at the damned thing after trying to muscle the springs for 3+ hours a few weeks ago. We then designed the door hinge tool you see in Tom's entry because the Lampredi tool (which is also in the photograph) is only really useful once the two springs have already been depressed 80% of the way, or on much lighter springs that you find on the v-12. We also had to fabricate a base for the Lampredi depressor we borrowed from David Carte, since its base is designed for the stud spacing on a v/12.

Before our tool was fabricated, dad called all the various luminary Ferrari vintage motor people in this country and overseas to see if anyone else had already fabricated such a tool - it appears that many who actually run their Lampredi fours converted to coil springs quite awhile ago! So if we ever break one of our mousetraps, we know who to call for spares!

1968 365 GT 2+2

s/n 11199

1955 s.II 500 Mondial

s/n 0556(0446)MD

1965 Alfa Romeo Giulia Sprint Speciale

s/n 11199

1955 s.II 500 Mondial

s/n 0556(0446)MD

1965 Alfa Romeo Giulia Sprint Speciale

-

John Vardanian

- Posts: 1908

- Joined: Wed Sep 04, 2002 12:13 am

- Location: San Francisco Area

Hi Bryan,

I assumed that the inline fours employed the same springs as the long block V12’s. That brings up another question. What safeguards excessive wear between the cam lobes and the inverted buckets? (are there in fact inverted buckets?) I have heard that the 4-cam 275GTB’s suffered from excessive wear in this area. I wonder how wear and tear was addressed in the little Lampredi?

As an aside, owners and mechanics sound pretty proud of the fact that their heads got converted to accept coils. I think it is a shame.

john

I assumed that the inline fours employed the same springs as the long block V12’s. That brings up another question. What safeguards excessive wear between the cam lobes and the inverted buckets? (are there in fact inverted buckets?) I have heard that the 4-cam 275GTB’s suffered from excessive wear in this area. I wonder how wear and tear was addressed in the little Lampredi?

As an aside, owners and mechanics sound pretty proud of the fact that their heads got converted to accept coils. I think it is a shame.

john

PF Coupe

Lampredi used mouse trap springs for two reasons; they enabled the use of a shorter valve and they - unlike coil springs - provide constant closing force on the valve. This was thought to reduce cam wear with high lift cams. I bet it may also affect engine characteristics at high revs. I agree it's a shame such updates are performed. Where do you stop?John Vardanian wrote:As an aside, owners and mechanics sound pretty proud of the fact that their heads got converted to accept coils. I think it is a shame.

250 GT 2+2 3197/GT

-

Michael Bayer

- Posts: 699

- Joined: Mon Nov 04, 2002 7:22 am

John The 4 cylinder springs are near an order of magnitude bigger and stronger than the 212 set I saw some months ago, I pass on the wear question to the Admiral who I am sure will comment. As to the conversions, having wrestled those huge springs unsuccessfully with Brian for some time, I could understand someone saying to heck with it and "cheating". I can assure you, Admiral Phillips is an absolute purest who would bend heaven and earth to find the way to do it right, his toll set created to assemble them worked wonderfully, and was a masterpiece of engineering. M!

Michael J. Bayer

330GT s/n 9727

365GTC4 s/n 14943

Dino Spider s/n 1193

330GT s/n 9727

365GTC4 s/n 14943

Dino Spider s/n 1193

-

John Vardanian

- Posts: 1908

- Joined: Wed Sep 04, 2002 12:13 am

- Location: San Francisco Area

Personally, if/when I go through my 128D, absent proper replacements, I will reuse the old mouse traps. I’d prefer compromised performance over the alternative. Another beauty of these springs is that each valve has two independent springs, so if one breaks the valve shouldn't drop. Hopefully there will be a sound or something alarming the owner once one of the two breaks.

An acquaintance had his 58 TR converted to coils years ago. The cutting of the heads caused passing of oil into coolant. I suppose once you go past the outer layer of the casting the heart is pretty porous.

john

An acquaintance had his 58 TR converted to coils years ago. The cutting of the heads caused passing of oil into coolant. I suppose once you go past the outer layer of the casting the heart is pretty porous.

john

PF Coupe

I would be interested to know if anyone has actually heard of cases where valve springs have failed. One additional reason for using mouse trap springs is that when operating, the spring material is bent, not twisted like in coil springs. To put it in other words, the mouse trap spring operates as a sort of curled up leaf spring meanwhile coil spring operates as a curled up torsion spring. I am under impression that the mouse trap spring design is not very critical to material characteristics, which is also one more reason for why they were used in the first place. Ferrari wanted his engines to be 100% reliable; and most of his engines were just that, thanks to very careful design.

250 GT 2+2 3197/GT

Hi All,

Robert Phillips sent me this about his valves:

You might be astonished at the size of the nested springs whose sole function is to keep the cam follower against the cam lobe. Their free standing height is 2 1/4 inches, the larger OD is 2 inches and the inner OD is 1 1/2 inches. The cam follower is mushroom shaped with a cross shaft with needle bearing supporting the roller of the cam follower. The valve clearance is determined by the thickness of the shim between the steel "button" and the bottom of the aluminum follower.

The face of the "button" is what contacts the top of the valve stem. The camshafts are hollow and oil fed from the main oil gallery. Each bearing and each cam lobe has an opening for the lubricating oil to exit the shaft. The cams sit in magnesium cam boxes fitted above the valves/valve springs, and the whole lot is in turn are covered by the valve cover. There are no belts as the cams and the three oil pumps and the water pump and the two distributors and the generator are all gear driven.

Enough for now.

Best regards,

Robert

Robert Phillips sent me this about his valves:

You might be astonished at the size of the nested springs whose sole function is to keep the cam follower against the cam lobe. Their free standing height is 2 1/4 inches, the larger OD is 2 inches and the inner OD is 1 1/2 inches. The cam follower is mushroom shaped with a cross shaft with needle bearing supporting the roller of the cam follower. The valve clearance is determined by the thickness of the shim between the steel "button" and the bottom of the aluminum follower.

The face of the "button" is what contacts the top of the valve stem. The camshafts are hollow and oil fed from the main oil gallery. Each bearing and each cam lobe has an opening for the lubricating oil to exit the shaft. The cams sit in magnesium cam boxes fitted above the valves/valve springs, and the whole lot is in turn are covered by the valve cover. There are no belts as the cams and the three oil pumps and the water pump and the two distributors and the generator are all gear driven.

Enough for now.

Best regards,

Robert

'63 330 America #5053

-

John Vardanian

- Posts: 1908

- Joined: Wed Sep 04, 2002 12:13 am

- Location: San Francisco Area

-

Chris Coios

There was a good article in Octane magazine sometime in the past few years about hairpin valve springs. They were used a lot in motorcycles. In addition to the bending vs. torsion operational characteristics, another difference, compared to a coil, is less inertia. With the hairpin spring, the valve stem can be shorter, reducing the mass. For the material, one difficult aspect of making the hairpin spring is controlling the finish. The wire finish must be without flaws to eliminate stress raisers which would lead to cracking and failure. I got the impression that the finish may be less critical with a coil.

-

John Vardanian

- Posts: 1908

- Joined: Wed Sep 04, 2002 12:13 am

- Location: San Francisco Area

Thanks Chris. The talk on the street is that there are no suitable replacement springs for these early engines-- which are why they are converted to coil. I wonder if anyone has done proper research to see if any other spring can be substituted--- like the early motor cycles'.

One thing I have learned is that small scale spring manufacturers can reproduce springs at reasonable cost, so long as you order in greater quantity. But you have to give them a sample unit or a good drawing. I learned this when I was trying to locate retraction springs for the drum brake shoes.

john

One thing I have learned is that small scale spring manufacturers can reproduce springs at reasonable cost, so long as you order in greater quantity. But you have to give them a sample unit or a good drawing. I learned this when I was trying to locate retraction springs for the drum brake shoes.

john

PF Coupe

-

Chris Coios

Hi John, I doubt that the typical hardware spring maker would be prepared for the challenge of engineering/manufacturing high RPM hairpin springs that lead a tough life. However, there must be engine component spring manufacturers who might be capable, but experience would be essential. Somewhere, I have notes on a French motor cycle specialty company that made hairpin springs. I think the aircraft industry would also be a source, because aircraft restorers no doubt also encounter hairpin valve springs. Chris

-

John Vardanian

- Posts: 1908

- Joined: Wed Sep 04, 2002 12:13 am

- Location: San Francisco Area

Posted for Robert:

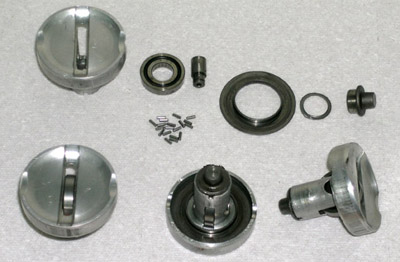

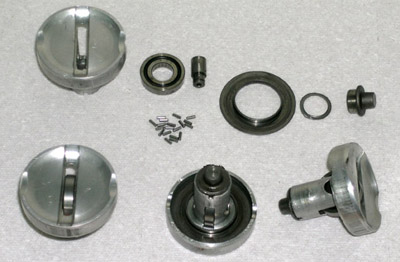

As John requested, the below photo is of four of the roller cam followers. The upper row is a roller cam follower completely disassembled which is comprised of the aluminum mushroom, the roller, the roller shaft, the needle bearings, the steel shim (to protect the aluminum from the ends of the springs), the valve clearance shim and the hardened steel button which actually makes contact with the head of the valve stem. The bottom row is simply different views of the assembly.

Tom

As John requested, the below photo is of four of the roller cam followers. The upper row is a roller cam follower completely disassembled which is comprised of the aluminum mushroom, the roller, the roller shaft, the needle bearings, the steel shim (to protect the aluminum from the ends of the springs), the valve clearance shim and the hardened steel button which actually makes contact with the head of the valve stem. The bottom row is simply different views of the assembly.

Tom

'63 330 America #5053

-

Chris Coios