Ferrari 250 Engine Assembly

Over the course of the past couple of weeks, I’ve been finding time to head down to Connecticut to assemble a 250GTE engine I have at Francois’ shop. I used the special Australian head gaskets to insure proper sealing of the heads. Leaks from other gaskets have me using these exclusively, and I’m not alone. Every few months I get another email from someone on the Internet searching why their fresh Ferrari engine rebuild has a leaking head gasket. The easy answer is they’re using the wrong gasket! The long answer goes back several years when I first encountered the problem 13 years ago but this is the most recent solution.

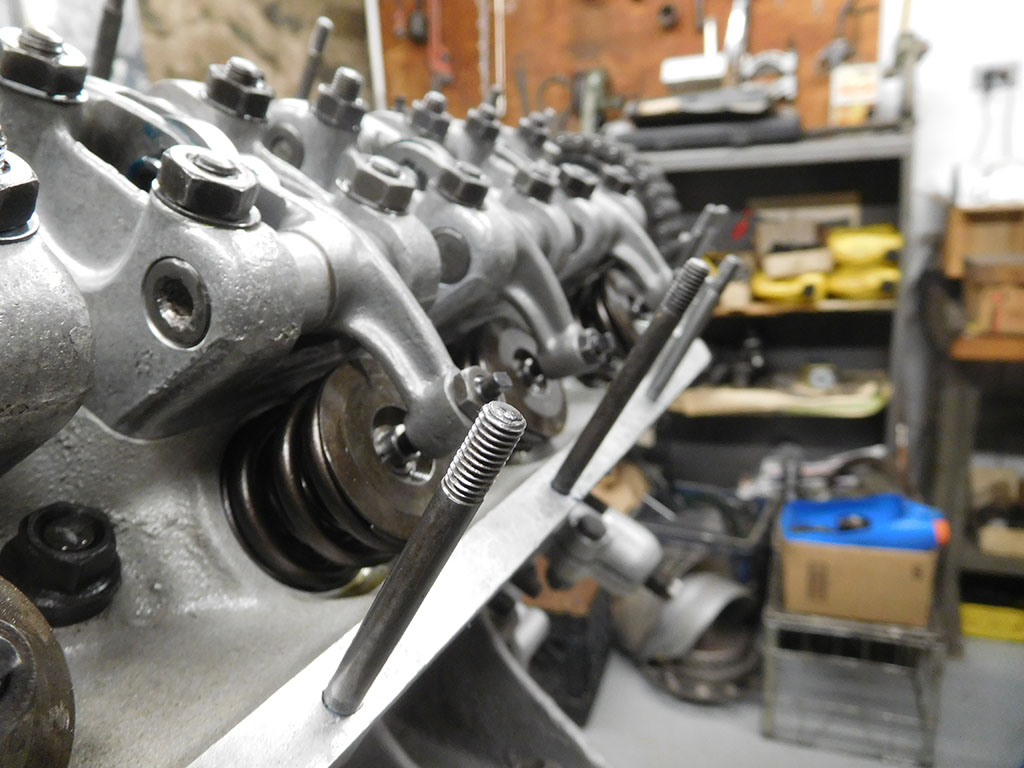

I finally got a chance to finish installing the heads and it’s all looking good!

With the heads installed, I had to install the valve cover studs. They vary in height to accommodate for the mounting of the spark plug tubes. Now was the time to make sure these correctly installed in the right places.

Francois and I worked together timing the new camshafts to the crankshaft. Without baseline marks to install the camshafts, we had to be very careful when the chain locked the cams in place. Just installing them roughly in place was stressful because there were no marks on these new cams. Once they were roughly installed, we accurately timed the camshafts in with the marks on the flywheel and no valves were bent in the process!

This engine had some wacky pieces installed that needed to to be replaced. One very disconcerting piece was one of the camshaft mounting plates. The plate on the left was what was evidently installed on one of the camshafts before it was disassembled. The one on the right is a stock piece. What was troubling was oil pressure is forced through the center of the camshaft when the engine is running, and this plate on the end of the camshaft contains the oil pressure of the engine. With the shape of the replacement plate, there would have been no oil pressure on that camshaft! We would even question with that much leakage, how much oil pressure was compromised in the rest of the engine!?

Francois fabricated a new plate and replaced the faulty one so this rebuilt engine will have much better oil pressure. With the cam timing done, I carefully installed all 5 bolts and lock washers making sure none of them fell down inside the timing chain case!

When I went to install the distributors, I found three studs were missing on the angle drive. These studs have 1.25 pitch threads on one side, and 1.00 pitch threads on the other, but Francois had the solution short of making new ones from scratch.

Francois dug into his parts stash and came up with a sacrificial angle drive to donate three studs to the GTE.

By the end of the second day down in CT, I got the cams in and timed along with the distributors.

The next time I get down to Francois’ shop, I’ll be installing the little parts and hoses to the engine to get it closer and closer to firing her up!